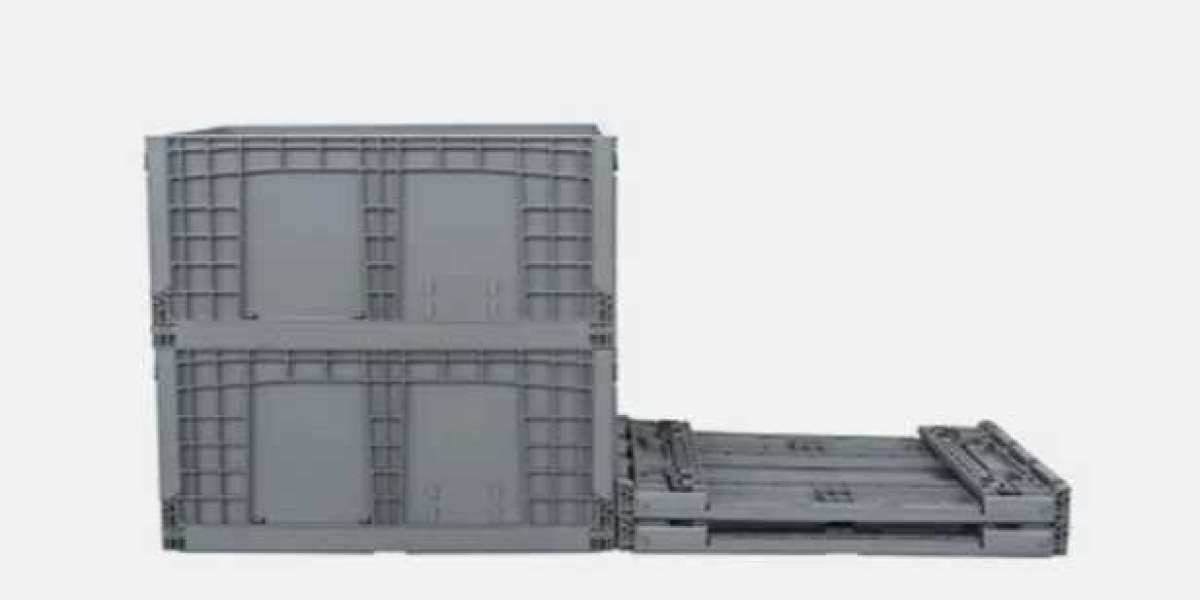

The best storage packaging option will ultimately depend on the type of order-picking system you implement. For example, in a case picking system, Plastic Storage Crates are your best choice because of their uniform size, strength, and stability. In goods-to-person settings, plastic totes are most compatible with AS/RS and high-speed conveyor systems. Here are the reasons to choose Plastic Storage Crate:

While cardboard can handle the lighter end, plastic is better at handling heavier loads. Plastic containers are also more durable, meaning they can withstand shock, vibration, and stress as they move in and out of the warehouse, and are picked, packed, and shipped.

In automated storage and retrieval systems (AS/RS), containers are typically stored in dense stacks on the warehouse floor. Because cardboard boxes come in all sizes and shapes, it's easy to have an uneven load or accidental spills. Plastic crates, on the other hand, are available in standardized sizes and can be stacked safely and securely.

Easily removes dust, dirt, and spills from plastic containers. They can also be sterilized, which is especially beneficial when strict health and safety standards are followed.

Is your warehouse hot and humid? Or a cold storage facility? Cardboard containers are easily deformed or degraded, while plastics are better able to withstand moisture and extreme conditions without losing structural integrity.

While cardboard boxes are relatively inexpensive to pre-purchase, they don't last long. Plastic Storage Crates can be reused—sometimes hundreds or thousands of times—which can significantly reduce waste. That can save you big in the long run, and ties in perfectly with your facility’s green initiatives.

Zhejiang Zhengji Plastic Industry Co., Ltd. is a Plastic Logistics Boxes manufacturer, its main products are Plastic Trolley, etc. Welcome to consult!