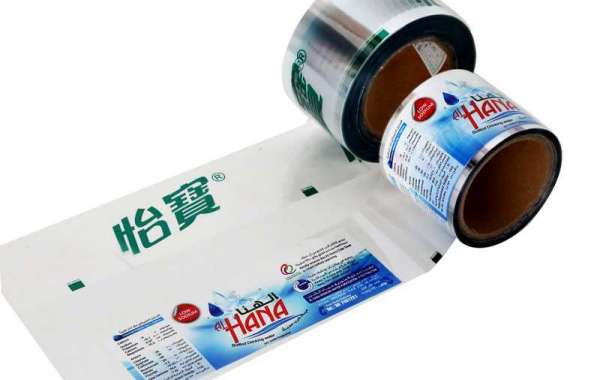

As an important link in the entire printing process, heat transfer label is closely related to other printing processes. How to control the stability of this process is an important guarantee for the quality of printing. Next, let’s take a look at the important factors that affect this process. .

1. Thermal transfer printing head

The speed of thermal transfer printing depends on the time required for each line of graphics and text. Therefore, the thermal transfer print head and the transfer paper should have good heat transfer properties, so that the heat generated by the heating element can quickly pass through the protective layer, the transfer paper substrate and the gap and finally transfer to the surface of the substrate to ensure that the ink has Enough transfer time.

2. Ink

When printing, the viscosity of different inks is directly related to the heating temperature, and the heating temperature and the viscosity of the ink should be strictly controlled. Generally, the closer the ink is to this state, the better the thermal transfer transfer performance.

3. The substrate of thermal transfer media transfer paper is generally divided into paper substrate, polyester substrate and celluloid substrate. Different substrates have different properties. For example, the material of the thermal transfer paper must be able to withstand the influence of the transfer temperature of the thermal transfer equipment and keep the properties unchanged.

4. Substrate

Substrates with a little rough surface have better print quality, which is a significant feature of thermal transfer. Because the rough surface of the substrate indicates that the substrate has a larger surface energy, the ink on the transfer paper can be transferred to the substrate well to obtain an ideal level and tone; but too rough will affect the ink quality Normal transfer is not conducive to the realization of the printing process.

With the development of thermal transfer technology, the range of thermal transfer equipment that can be transferred has been continuously expanded, and it has also been applied to many industries. For example, thermal transfer equipment technology is also applied in the plastic processing industry. The process of thermal transfer equipment has the advantages of simple, fast, pollution-free, rich prints, bright colors, high precision, and good picture quality.

Gbao has heat transfer machine for sale. You can contact us if you are interested!