Heat transfer machinery, when producing and processing heat transfer printing film, the temperature is usually maintained within the range of 5-30 ℃. And prevent heat source, otherwise it will have a bad impact on the membrane. Heat transfer machinery, film making should have professional process line, heat sealing equipment, testing equipment and necessary cutting. Moreover, the equipment for making heat transfer machinery and film need to be used and pass the national verification.

Heat transfer machinery, production and processing in the production of heat transfer film, it is divided into cutting, connection, production and processing of accessories, transportation and packaging. The production process includes: membrane material acceptance, membrane cutting, and detection of cutting geometric dimensions. The confirmation of technical parameters, the connection strength test of the membrane, the shape test of the membrane, cleaning and packaging are also marked.

In addition, process design documents shall be formulated for the production of heat transfer machinery and film, including the detection of film materials, the confirmation of cutting diaphragm, the pre adjustment of tensile length, processes and acceptance methods, heat transfer machinery, quality standards for production, processing and production, etc.

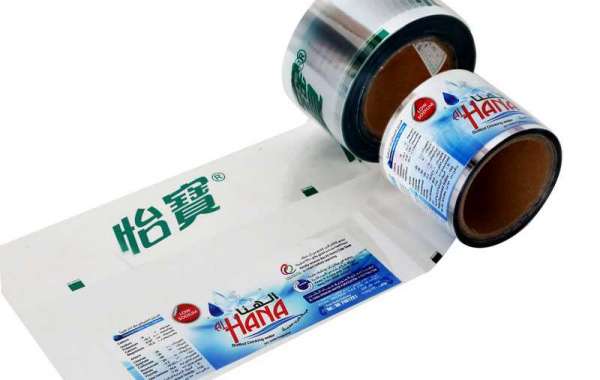

Our heat transfer labels is for sale! Welcome to your come and purchase!