What is linen fabric?

Flax is a type of linen fabric, mainly used in household products. Although flax is similar to cotton, it is made of fiber from the stem of the flax plant, rather than bolls that grow around cotton seeds.

In hot and humid climates, clothing made of linen is desirable. Unlike cotton, cotton tends to retain moisture for a long period of time, while linen dries quickly, which helps reduce heat retention under overheated conditions.

However, manufacturing linen requires more time and resources than cotton, which has led to a steady decline in the popularity of this fabric since the invention of the cotton gin. However, the unique ideal properties of linen prevent the global production of this textile from completely halting, and certain countries, such as China, continue to produce linen in large quantities.

Before we continue, it is important to clarify the difference between the phrase "linen" and "linen". Although "linen" is used to refer to flax fibers that are commonly used in household items and certain forms of clothing, "linen" is a phrase people use to refer to certain types of household items and clothing, but may be composed of linen fibers. Outside the fiber. The term "linen" can be traced back to the era when almost all underwear, bed sheets, and towels were made of linen, but nowadays, this untimely phrase can sometimes be confusing.

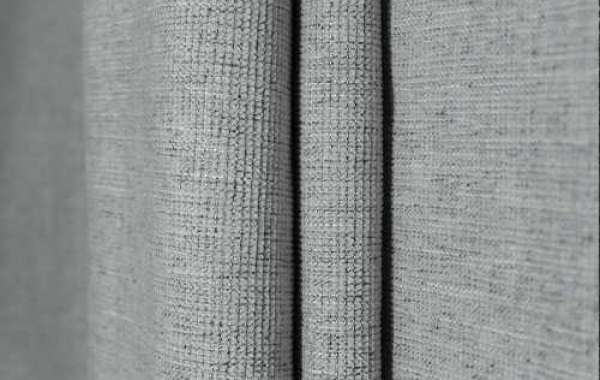

Therefore, many woven imitation linen fabric are used in the manufacture of furniture such as curtains and sofas.

The history of linen

Although there is little evidence from prehistoric times, the people of the Neolithic Age in Europe seem to have used linen to make textiles as early as 36,000 years ago. Therefore, linen is one of the longest-produced textiles, and its history may be longer than the oldest evidence found in modern archaeology.

The next historical evidence for the use of flax comes from ancient houses built on the shores of a Swiss lake about 10,000 years ago. According to archaeologists, flax was first domesticated in ancient Mesopotamia. Although the use of linen to make clothing in Mesopotamia was mainly reserved for the ruling class, the use of linen in ancient Egypt was much more widespread.

Due to the climate in Egypt, it is necessary to design clothing that can resist the sun's rays and allow the sweat to cool down quickly. Since linen is naturally white, this fabric is the obvious choice, and its lack of breathability and moisture retention quickly made it the most popular and valuable textile in Egypt.

In fact, the ancient Egyptians sometimes used linen as a real currency. This fabric is also used to make shrouds and wrappers for mummies.

The ancient Greeks used linen to make clothing and household items, and later the Phoenicians introduced linen production to Western Europe. However, historical records indicate that it was not until the 12th century AD that the major European powers made efforts to regulate flax production in agricultural communities.

Later, Ireland became the center of European flax production, and in the 18th century, the town of Belfast was called "Linenopolis" because of its prosperous line trade. Flax remained popular throughout the colonial era, but as cotton production became cheaper and easier, the once central role of flax in the European textile economy gradually weakened.

Flax Today

Today, linen is mainly a niche product, which is still being produced to make a few textile products. Despite its long history, linen is no longer popular because the process of making this fabric is time-consuming and laborious. The irony is that thousands of years ago, production difficulties initially inhibited flax production; although the challenges faced by today's production line producers are very different from those of ancient times, the production of this fabric is still very demanding and costly.

How is linen fabric made?

The constituent material of the flax fabric is the cellulose fiber in the stem of the flax plant. Like the stems of many similar plants, flax stems consist of woody, reed inner parts and fibrous, gluten outer parts.

To prepare for flax production, the manufacturer of this fiber first separated the flax fiber from the wooden interior of the flax stem. Traditionally, this step was done by soaking raw flax stalks, but nowadays, manufacturers may use chemicals to achieve the same effect. Before flax fibers are spun into yarns, these chemicals are washed away, but residual toxic substances may remain on the chemically separated flax fibers.

1. Planting

Flax plants can be harvested after about 100 days of growth. Because flax plants are not heat resistant, they must be planted during cooler times of the year to avoid crop death.

2. Growth

These days, flax seeds are usually sown by machines. Since flax plants cannot effectively prevent the invasion of weeds, herbicides and farming are usually used to prevent the yield of flax crops from decreasing.

3. Harvest

Once the flax stems turn yellow and the seeds brown, these plants can be harvested. Although flax can be harvested by hand, machines are usually used for this process.

4. Fiber separation

After the flax stems are harvested, they are processed by machines that remove leaves and seeds. Then, the manufacturer separates the fibrous outer stem of flax from its soft wooden interior. This process is called retting, and unless it is done expertly, the delicate flax fibers used in textile production may be damaged.

5. Break

Next, the decomposed flax stalk is broken up, thereby separating the useless outer fibers of the flax stalk from the available inner fibers. To accomplish this step, the flax stems are transported to rollers that crush them, and then a rotating paddle removes the outer layer of fibers from the stems.

6. Grooming

Now that the inner fibers are separated from the other fibers, they can be carded into thin threads. Once the fibers are carded, they can be spun.

7. Spinning

The spinning of flax yarn used to be done with pedal-type flax wheels, but now flax producers use industrial machines to complete this process. To spin flax fibers, these short, combed fibers are connected to a device called a spreader, and the resulting string is called a roving, which is then ready to be spun.

8. Coiling

After spinning on a spinning frame, the resulting yarn is wound on a bobbin. In order to ensure that the flax yarn does not fall apart, it is necessary to carry out this reeling process in a humid environment and pass the spun yarn through a hot water bath to further ensure the cohesion of the yarn.

9. Drying

Finally, the flax manufacturer dries the finished yarn and winds it onto a spool. The yarn is then ready to be dyed, processed, and made into clothing, household goods, or other types of textile products.

After these steps, curtain fabric wholesaler will choose machine-made linen fabrics to make curtains.