While small in size and simple in design, bushings play an important role in high-stress applications where vibrations are problematic. Automotive suspension systems, for example, often feature control arms with bushings that connect the vehicle’s struts or shocks to the chassis. The control arms themselves are metal, but the bushings are padded with a soft material that dampens vibrations created while driving. Without bushings, controls arms wouldn’t be able to effective absorb vibrations, resulting in a more bumpy ride for the vehicle’s driver and passengers.

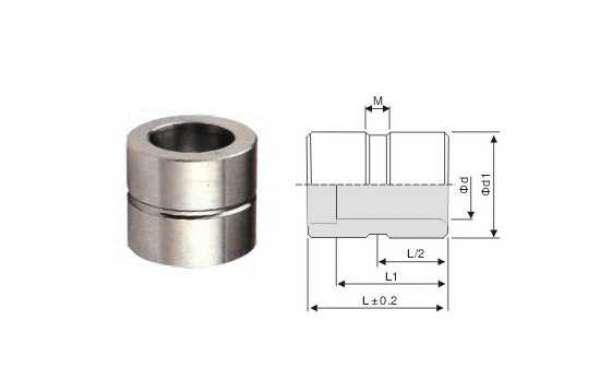

How Bushings Are Designed

Most Guide bush features a similar design consisting of a hollow, cylindrical shape. The hollow interior allows bushings to separate two metal objects, and because they are made of soft materials, they reduce vibrations as well as noise created by those objects. This otherwise simple design makes bushings an essential component in automotive suspension systems, sway bars, transmission gear sticks, doors, windshields and other applications in which vibrations are common.

The History of Bushings

The modern-day bushing was invented by American entrepreneur and founder of Chrysler Corporation, Walter Chrysler, in the 1930s. Chrysler proposed his idea to other corporate executives for use in a new car. Reports show that Chrysler described the bushings as being “the most radical feature” of the company’s new Plymouth model, significantly reducing the amount of vibrations and noise created by the car while driving. Chrysler’s idea was an instant success, essentially transforming the way in which nearly all vehicles are manufactured.

Rubber Bushings

Rubber is one of the most common materials in which bushings are made. They are inexpensive, readily available and able to absorb most vibrations and noise transmitted by the objects to which they are attached. Unfortunately, rubber bushings are susceptible to deterioration when exposed to heat, cold or oil. Over time, exposure to these elements may cause the rubber material to crack and wear away.

Neoprene Bushings

Another common material in which bushings are made is neoprene. Neoprene looks and feels like rubber, but it’s a completely different material with its own properties. Rubber is made of latex, which comes from some 200 plants and trees. In comparison, neoprene is a synthetic material that’s made by polymerizing chloroprene. Technical jargon aside, neoprene is a stronger and more robust material that’s better suited for bushings than rubber. While rubber is sensitive to heat, neoprene can withstand temperatures of up to 200 degrees. And unlike rubber, neoprene doesn’t deteriorate when exposed to oil.

We are one of the Mold parts manufacturer and welcome you to come and purchase!