Basically, the function of an Ejector sleeve in a mold is to eject either an entire finish molded piece part or apply ejection force to some portion of the molded piece part to assist with part ejection, in combination with other ejection features designed into the mold.

There are also cases where the ejector sleeve contributes to partial ejection or repositioning of the molded part, or the sleeve functions to “shut off” some feature for multi-shot molding. These later ejector sleeve applications function principally to support the multi-shot requirement and tend to be challenging as well as unique.

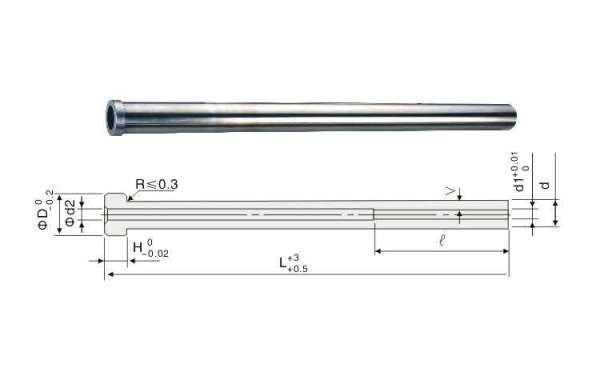

Sleeves can have actual molding detail on the inside and/or outside surface or function with shut off features or just have the basic “molding surface” on the very end of the sleeve, which in effect becomes the molded surface where the ejection force is applied. The mold design and piece part design determine the exact functionality, quantities and sizes of sleeves for a given mold and the relative piece part.

The following information is intended to aid in identifying common causes of failure as well as minimize maintenance with ejector sleeve assemblies, highlighting just some of the basic criteria that can be used in making ejector sleeves.

Tool steel is still the most common selected sleeve material used by mold-makers and designers, but aluminum bronze alloys are another option.

It is important to understand that adherence to specific procedures must be followed to yield predictable results when using tool steel materials for ejector sleeves. It is also important to understand that not all moldmakers, manufacturers of standard off-the-shelf sleeves or custom sleeve manufacturers neither agree with nor utilize the procedures suggested in this article.

Some sleeve manufacturers have taken the position that if they make the sleeves and the customer agrees to the manufacturer recommended material choice, running fits, clearances and coatings, a warranty for the sleeve life for an excess of three years in continuous running molds will be given (obviously this warranty would not be valid for component misuse or machine malfunction).

The basics of making ejector sleeves when using tool steel do require specific steps in manufacturing procedures as well as heat treatment steps that assure the maximum attainable life and performance possible. Even the maximum attainable life is often far less than expected with a heat treated and precision manufactured component.

Sleeve failures can present as “going out of round,” where the component measures to be “egg shaped” without evidence of any wear or metal loss. This condition leads to a combination of tightness in the component assembly while at the same time excess clearance to the component assembly, which may present as flash on the piece part.

Galling is also a common problem, which is typically the result of hardness or metallurgical incompatibility, or incorrect running fit allowances or lack of lubrication in the assembly. These failures or conditions when using tool steel sleeves can best be categorized and attributable to not following required manufacturing procedures and where the development of out of round, size of shape changes relates to a condition that is defined by metallurgists as retained Austenite.

Retained austenite is a metallurgical structure or phase that occurs in the heat treatment of tool steel and is generally most notable and problematic in tubular parts, such as ejector sleeves. To minimize the presence or the effects of the retained austenite condition on the finish machined sleeves, a combination of machining and heat treatment processing needs to be followed.

The steps are as follows:

Rough machine sleeves adding 1/16″ oversize stock to all finish dimensional requirements.

Then stress-relieve or anneal the sleeves.

After the stress relieve process, further machine the components leaving stock allowance for finishing after heat treatment.At this point then heat treat the component as specified for the tool steel to final hardness.

Now this is the important part, to minimize the potential for retained austenite, include without exception, a double draw and deep freeze process.

Then finish machine the components to final dimensions. Anything less than using these six steps, leaves an open field for problems with the tool steel-based sleeve or the assembly.

Rotating Core Applications

In ejector sleeve applications with rotating cores, such as unscrewing molds for closures for packaging, not only is there potential lineal wear from the straight line ejector sleeve stroke, there is also the potential for rotational wear from unscrewing the part and then the rotary motion again to reposition thread orientation.

If you want to buy Injection plastic mold, welcome to send us messagesz!