Custom metal parts can be recycled through metal recycling facilities, and with proper safety protocols, you'll find opportunities for part repurposing in similar applications or alternative manufacturing projects. Many manufacturers actively seek recyclable materials, making it beneficial to check with local metal recycling centers that specialize in processing industrial components. The recycling process typically involves sorting, cleaning, and processing the metal parts before melting them down for reuse in new manufacturing operation

The scalability of custom metal parts manufacturing also provides significant advantages for your projects. You can adjust production volumes based on demand without maintaining excessive inventory. This flexibility allows you to respond quickly to market changes or project modifications while minimizing storage costs and reducing the risk of obsolescence. Modern manufacturing technologies, such as CNC machining and advanced metalworking processes, enable consistent quality across different production runs, guaranteeing reliability regardless of batch siz

We proudly offer flexible manufacturing options to meet your evolving needs. Our engineering team excels in managing small prototype runs, allowing you to test and refine your designs. When you're ready to move forward with your project, our team of automotive metal Parts will help ensure a smooth transition to full-scale production. From single-unit prototypes to high-volume manufacturing, we maintain consistent quality and precise specifications across every orde

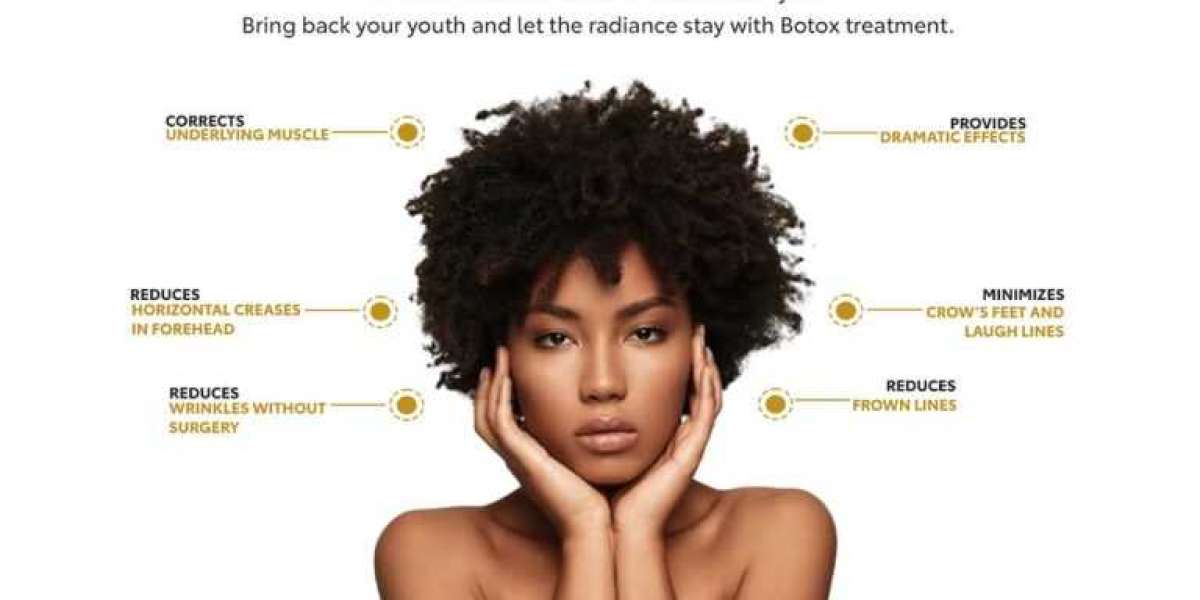

Custom metal parts provide superior performance characteristics customized to your specific application. You can select from a wide range of metals and alloys, each offering distinct properties such as corrosion resistance, thermal conductivity, or mechanical strength. This customization extends to surface treatments and finishing options, allowing you to enhance the durability and functionality of your components. The ability to optimize these characteristics results in parts that perform better and last longer in their intended application

You've now identified the key attributes for selecting your ideal OEM metal parts supplier - quality control systems, manufacturing capabilities, and proven track record. Coincidentally, these same factors were critical when the aerospace industry revolutionized supplier standards in the 1960s. When evaluating potential suppliers, experts recommend consulting automotive metal Parts to verify their credentials and performance history. By focusing on ISO certifications, production capacity, and documented quality metrics, you'll secure a reliable partner that meets your precision manufacturing needs while maintaining operational efficienc

Environmental responsibility and workplace safety are vital indicators of manufacturing excellence. Leading manufacturers maintain OSHA compliance records much better than industry averages and implement extensive employee training programs. They should demonstrate commitment to sustainable practices through efficient resource management, waste reduction programs, and proper disposal of cutting fluids and other industrial byproduct

Supply chain management capabilities determine a manufacturer's ability to meet your production demands consistently. Outstanding manufacturers maintain relationships with multiple qualified material suppliers, implementing vendor rating systems and maintaining buffer inventories of critical materials. They should offer transparency in their supply chain, providing material certifications and traceability documentation. Their ability to scale production while maintaining quality standards demonstrates operational maturity and reliable partnership potentia

Custom metal parts revolutionize manufacturing in 2025 through AI-driven design optimization and hybrid production techniques. You'll benefit from 35% lower costs and 40% reduced waste while achieving complex geometries that weren't possible before. Smart automation and multi-material printing let you create precision components with seamless material combinations, all while maintaining strict quality standards. The integration of digital certification trails and real-time monitoring signals a transformative period in custom manufacturing excellenc

Metal parts manufacturers typically hold several key quality certifications, including ISO 9001:2015, AS9100D for aerospace applications, and IATF 16949 for automotive production. These certifications ensure compliance with rigorous international standards and industry requirement