Mochi Ice Cream Machine is used to stir the dough of wafers. The dough that has been stirred in the mixing tank is transported by the slurry pump to the transfer storage tank for later use. The dough is added by the slurry transfer pump when the oven needs it. After pressing, it is transported to the oven through the pipeline

The oven is very important in the wafer production line. The wafer baking system uses gas to heat the baking plate, and the batter is automatically controlled to cover the baking plate until the baked wafer is out of the oven. Evenly bake and produce wafers that meet the quality for further processing. A manual temperature control cabinet is provided to control the temperature of the oven.

The wafer splicer accepts the baked wafers and cleans the remaining powder on the wafers, and sends them to the cooling channel, gently conveying the hot wafers so that they will not be damaged. All food contact parts are made of SUS304 Stainless steel and food grade PU belt manufacturing.

The cold film machine improves the natural cooling effect of the wafer. This machine is used to alleviate the effect of the thermal stress on the wafer during baking. If the wafer cannot be cooled gently, due to the influence of thermal stress, it will be easily broken by a small impact. This machine is also called thermal stress relaxation machine. This is an improved system that can increase the width and height of the transport arm according to your requirements.

The cream coating machine is an important machine that determines the distribution of the number of wafers and cream layers. It has the following functions: spread the cream layer on the cooled wafer, evenly spread the cream and spread the layers of cream on each layer of cake, and then Slightly pressurize the cake and cream to combine with each other. The number of cream layers and wafers can be adjusted to 3, 4, 5, etc. as needed. The machine automatically calculates the number of layers adjusted. The filling roller is equipped with an automatic temperature continuous control device. The thickness of each cream layer can also be adjusted.

The conveyor can deliver the pressed wafer blocks to the cake cutting machine as required.

The cake cutting machine is a steel wire cutting machine, used to cut wafer cakes. The size can be pre-controlled as required. The cutting action can be completed continuously. The machine is mechanically interconnected and electronically controlled, so it can be adjusted gently by the machine. The two-way cutting and conversion can be completed automatically. The surface of the structure in contact with food is made of SUS304 stainless steel.

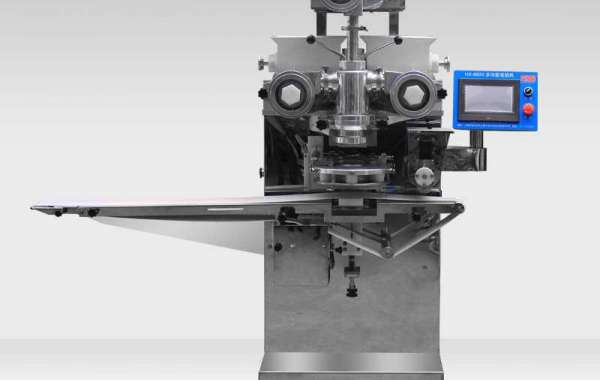

This device of Cookies Making Machine manufacturers is a SUS304 stainless steel mixer used to produce cream. It is composed of a mixer in the form of a mixing device. It is driven by a 4.5Kw motor. The tumbling system used to discharge the cream from the mixer consists of a 0.55Kw power. Driven by a motor, the mixing time depends on the composition of the cream.