A critical component in Bucket Mould design is choosing the correct gate. The function of the gate is a simple concept, but choosing the wrong type of gating can cause several problems during processing. In this post, we're going to discuss several different kinds of gate designs and how they're used.

When choosing the gate type/location for a molded part, there are a few important factors to consider. The first is how the mold will be designed and where a gate can be located. Part orientation in the mold, show surface location, and action locations can limit the options for gating. Further design considerations are material selection, part volume/size and production functionality.

Some plastics are more sensitive to over-heating conditions. This is known as shear heating. Any time plastic is forced through a restricted area, there's some amount of shear heating. Attempting to fill a large plastic part with a small gate will create excessive shear heating and could degrade the plastic. With that in mind, gate designs like submarine gates have limitations to the maximum size of the gate, which may eliminate the gate design as a possibility for larger parts. Furthermore, the gate could freeze off before the part is full.

Gate freeze is an important aspect of the injection molding process. Generally speaking, gates need to be large enough to fill out the cavity properly but small enough to "seal" the cavity (gate freeze). Gate freeze should occur when the cavity is completely packed out and ready to start the cooling process. Since the gate is small, it should cool off relatively quickly compared to the molded part or the feed system. Gate freeze allows the part to become isolated from the feed system and for the injection molding machine to move onto the cooling/charging phase of the molding process.

The function of the mold in the production environment is another consideration. A defining characteristic of the different kinds of gates is whether they break from the molded part automatically or require trimming. In higher volume applications, it becomes less feasible for an operator to trim gates manually. In this case, either factoring in robotic gate cutting (Nipping) or changing gate designs should be factored in. Scrap costs generated from cold runner systems may justify a hot runner where zero scrap is generated.

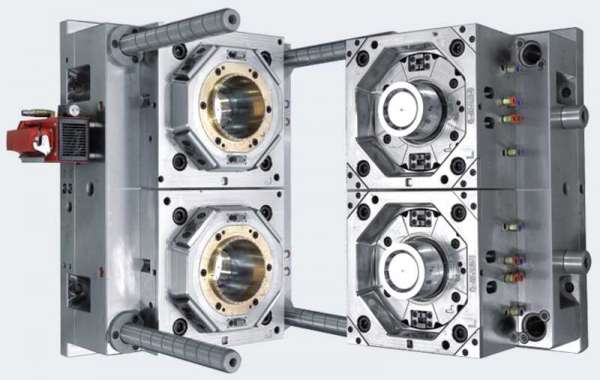

We are a professional molding company, sell different design of mold, Paint Pail Mould is one of them,welcome to visit our website.