Possible causes of exhaust instability in Chipper Shredder are blocked exhaust holes, changes in vacuum or changes in volatiles in raw materials, etc. The possible ways to improve exhaust efficiency are:

- Increase the barrel temperature in the first stage.

- Increase the vacuum degree in the exhaust hole of the comprehensive crusher.

- Pre-heat the raw materials.

- Use stripping agent.

The screw design can also greatly affect the exhaust efficiency, and the multi-threaded exhaust section can improve the exhaust. In addition, it is very important that the polymer is completely melted in the first stage of the screw. Setting a tank mixing section at the end of the first stage of the screw will help ensure complete melting.

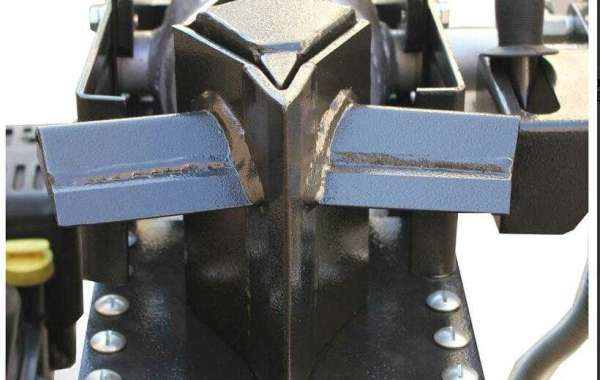

The above is the knowledge of the reasons for the instability of the exhaust of Log Splitter. You are welcome to consult us if you do not understand the above. Our company insists on providing our customers with products that satisfy you.