Here’s the basic equipment and considerations to make when you get started with the leap to automatic printing.

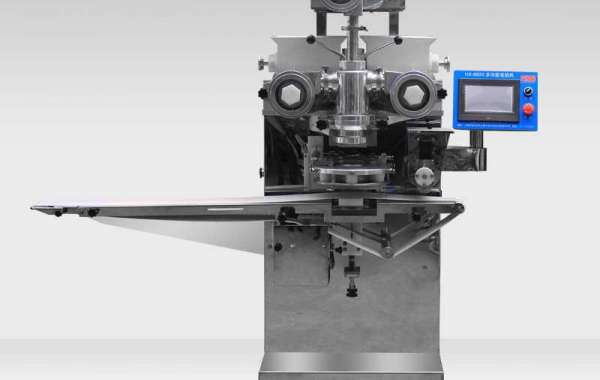

An automatic press. Whether you buy used Syringe Silk Screen Printing Machine or a brand new press, you’ll want to invest in a press that will last. This typically means buying a little bit more press than you think you’ll need. Keep in mind that an “8 color press” doesn’t mean you’ll be able to print 8 colors right off the bat. I like to advise shops to start with a 10 color press if possible. Then your shop can grow into the press and still unlock the additional benefits of automatic printing without a giant investment.

Flashes. You’ll likely want two flash dryer units per press. More is unreasonable.

A quality compressor. Your air compressor is not something to overlook or skimp on – your entire shop stops if your compressor breaks down. Keep up on maintenance and get help if you’re not sure about your compressor.

A properly sized conveyor dryer for curing ink. It’s likely the dryer you use for manual printing won’t be able to handle 4-6x the number of shirts going through it. You may not need to invest in a 72” dryer right off the bat, but you will certainly need something that can handle a higher volume of shirts.

Air lines. Since presses utilize pneumatics, you’ll need to run air lines in your shop. Most elect to have these overhead, but some shops have routed them through their floor. For easy maintenance and troubleshooting, air lines should be accessible with minimal disruption or effort. If you’re only setting up one press, you can likely run the basic air lines yourself. If you’re new or concerned you’re not going to do it correctly, get professional assistance from your press manufacturer.

Electrical drops. You need to carefully consider whether your shop has the necessary three-phase power to handle your needs. Your machines need a lot of power! A licensed electrician will help you determine whether your building will have the capacity to handle the increased load.

Screen printing management software. You may think you can wait on software – but managing your business is crucial. Printavo was built with screen print shops in mind. From online stores to approvals to invoicing and payments, Printavo's team is here to help you succeed.

If you have interests about syringe machine, welcome to send us messages.