Seamless integration with production line

Our heat transfer machine is small and light, and can be easily integrated with all packaging equipment. With the dedicated brackets and accessories provided, the most unique application integration can be easily and neatly

Low-cost printing of variable messages

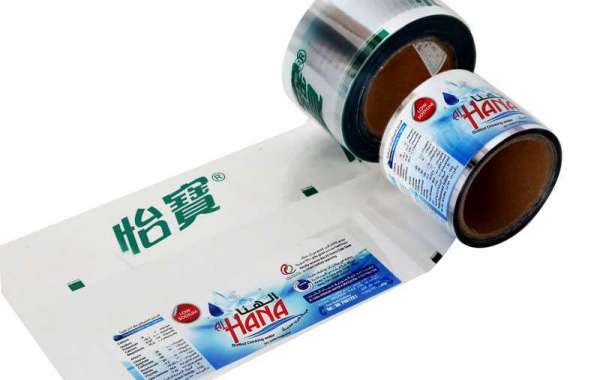

The heat transfer machine is freely programmable and can generate variable data for each print. This high-resolution printhead can print text, graphics, batch numbers, real-time dates and barcodes. This perfect printing technology was originally used for printing directly on flexible film packaging materials, so instead of labels, the printing cost was significantly reduced.

Provide affordable solutions for your industry

The latest TTO technology minimizes the amount of ribbon used by ensuring a 0.5 mm print pitch. As a result, thermal transfer inkjet printers have become an economical solution for the flexible packaging industry. With TTO, you can also plan production line downtime without having to manage unplanned maintenance. After knowing the amount of inkjet code per roll of ribbon, you can accurately calculate the interval between ribbon replacement. The simple design of the ribbon cassette also makes the ribbon replacement fast and convenient, minimizing the impact of the production line.

Production flexibility

Using thermal transfer technology, it is possible to mark on stationary (intermittent) products or continuously moving (continuous) products.

If you are interested in heat transfer label, welcome to contact us!