Traditional solar cells are made of silicon, a conductive material. Manufacturers shape virgin silicon wafers into uniformly sized silicon cells.

Solar cells can be monocrystalline (cut from a single silicon source) or polycrystalline (from multiple sources).

Traditional solar cells are made of silicon, a conductive material. Manufacturers shape virgin silicon wafers into uniformly sized silicon cells.

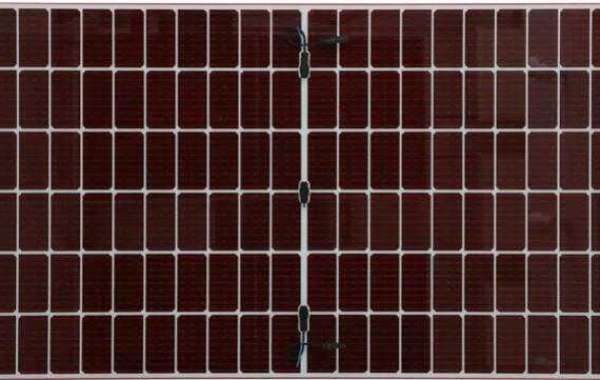

Mono solar panels contain cells cut from monocrystalline silicon ingots. The components of these cells are purer because each cell is made from a single piece of silicon.

Polycrystalline solar cells are made of multiple pieces of silicon mixed together. Smaller silicon wafers are molded and processed to make solar cells. This process is less wasteful because hardly any raw materials are thrown away during the manufacturing process.

P-type cells are typically made from boron-doped silicon wafers. Since boron has one less electron than silicon, it produces a positively charged battery. P-type cells suffer from light-induced degradation, which results in a drop in initial output due to light exposure. This has historically been the most common treatment method for solar cells.

N-type cells are doped with phosphorus, which has one more electron than silicon, giving the cell a negative charge. N-type cells are not affected by boron-oxygen deficiency and thus are not affected by light-induced degradation (LID). As you might expect, these are positioned as premium options because they degrade less over the life of the panel. When you consider the lower cost of P-type cells, it is often worthwhile to choose a cheaper and more degraded module than a more expensive and slightly less degraded panel. But that assessment could change as N-type technology advances and costs fall.

Jiaxing Fuying Composite Materials Co., Ltd. is a mono solar panels manufacturer and supplier in China. It sells PV solar panels and other products.