How to place a straight ejector pin or a sling ejector pin on the mold design? Here are some guidelines for placing thimbles in the mold design. Hope it can help you solve the problem in injection molding.

- Ejector position

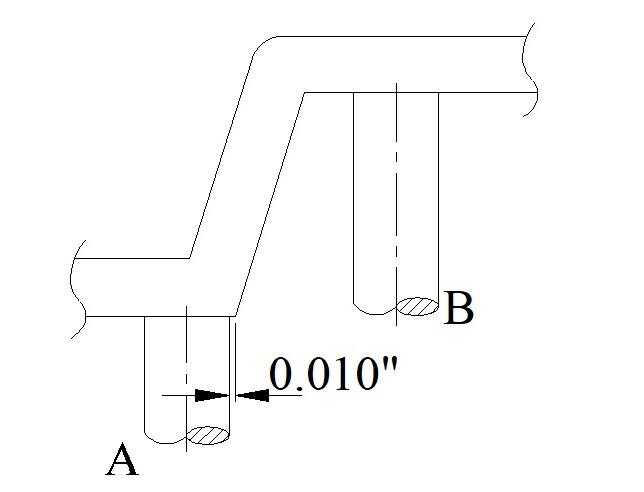

The distance from the pin to the edge of the plastic part should be 0.04 to 0.10 inches.

Place the pins as A pins on the bottom of the part, leaving 0.01" on the edge of the core. Not suitable for placement on top of parts as B pins.

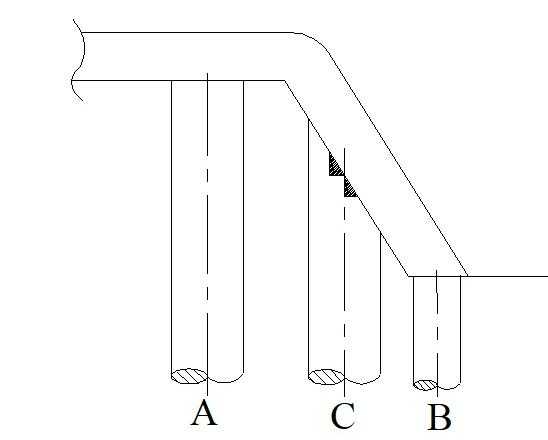

The position is as shown below, A is better than B, and B is better than C.

If there is no option but to place the pin in the C position, it is best to add some small steps to the pin to increase the ejection force.

If you must place the pin in the A position when there is no better option.

The pins must be lowered 0.0005 inches from the parting line, the same depth as the vent.

Added spring under the return pin to protect the ejector pin.

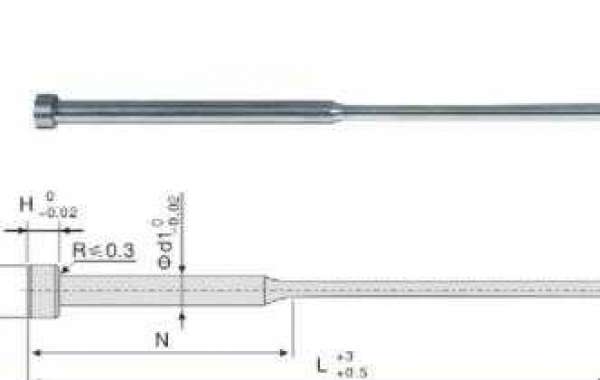

- Pin fit length and clearance.

- If the ejector pin is placed on a non-flat surface of the part, the ejector pin should be locked.

TAIZHOU HUANGYAN JINHONG MOULD PARTS CO., LTD. is an injection mold maker from China Ejector sleeve, its own plastic mold factory specializes in the production of plastic compression springs, positioning components, and other products.