Hot stamping hot printing technology is commonly known as hot stamping. It is a special printing process that does not use ink. It uses a certain pressure and temperature to use the template installed on the hot stamping machine to make the printed matter and the hot stamping foil press each other in a short time. Transfer the metal foil or pigment foil to the surface of the hot-stamped print according to the graphics and text of the hot stamping template. The bronzing technology is environmentally friendly and clean, and it is suitable for various materials such as plastic, glass, and paper. Because of its unique surface decoration effect, it is loved by the public, and its unique surface decoration comes from bronzing paper.

Hot stamping is a hot pad printing process for hot stamping anodized aluminum foil (hot stamping paper) on the surface of the substrate under a certain temperature and pressure. The notable functions it has are as follows:

1) Hot stamping products on the whole surface, no ink residue;

2) There is no unpleasant smell such as ink, and the air is pollution-free;

3) The color pattern can be hot stamped at one time, reducing loss;

4) The process is simple, the production management and flow are smooth, and the product quality insurance coefficient is large;

5) Wide processing range, suitable for paper, wood, plastic, leather, etc.

And just as the so-called gold has no perfection and no one is perfect, the bronzing itself also has certain defects, which are reflected in:

1) Not suitable for hot stamping substrates with uneven surface or matte surface;

2) Metal, glass, ceramic, nylon, and other products are generally not suitable for hot stamping unless they are painted or screen printed;

3) Matching the pattern color and the background color of the workpiece: during hot stamping, the color of anodized aluminum (gold, silver, copper, inner red, inner blue) has a strong hiding power, even if the background color of the workpiece is black, it can be completely covered; but When using lighter color transfer paper such as white and yellow for hot stamping on a black background, its covering effect is not as good as pad printing and screen printing.

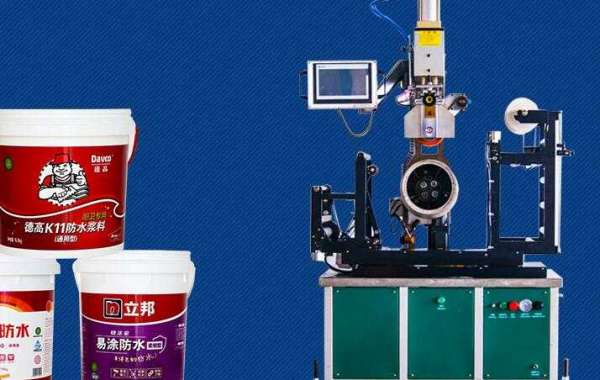

Wenling Gaobao Industrial Co., Ltd. is a heat transfer machine manufacturer, And also a heat press machine manufacturer, we provide a Fully automatic heat transfer printing machine, plastic bucket heat transfer machine, and other printing equipment.