The perfect bronzing effect by the hot stamping machine mainly depends on the level of coordination of temperature, pressure, and bronzing speed. Therefore, to control the bronzing quality, a reasonable bronzing temperature, bronzing pressure, and bronzing speed should be mastered. Only by creating good conditions for bronzing can the quality of bronzing be guaranteed.

- Temperature: Temperature has a very important effect on hot stamping. The temperature must be controlled within the corresponding range to make the dyed resin layer and the adhesive melt appropriately to ensure the good transfer of the aluminum layer. If the temperature is too high and the melting is too high, the anodized aluminum around the hot stamping graphic will also melt and fall off to produce a paste. At the same time, the high temperature will also chemically change the anodized aluminum dyeing resin and aluminum layer, reducing the brightness of the hot stamping product and losing its metallic luster. It can even make the mark appear foggy or blistering; but if the temperature is too low and the melting is insufficient, it will also cause the hot stamping or the hot stamping to be weak, the imprint will not be firm, easy to fall off, or the pen will be broken and the imprint will become blurred.

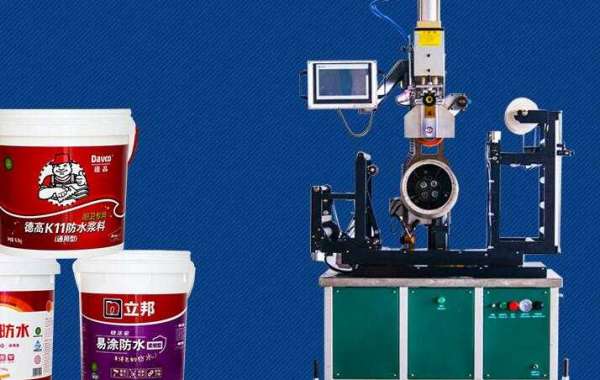

- Environment: The machine should be installed in a dry, ventilated, well-lit, and easy-to-operate place.

- Pressure: Even if the temperature is right, if the pressure is not enough, the anodized aluminum cannot be transferred to the substrate well, which will cause problems such as false imprints and patterns; on the contrary, if the pressure is too high, the gasket and the substrate will be compressed If the deformation is too large, the print will be thick, even sticky and stale. Usually, the hot stamping pressure should be adjusted appropriately to achieve no color fading and good adhesion fastness as the criterion. At the same time, the hot stamping foil should not be installed too tightly or too loosely. If it is too tight, the writing will be missing and broken; if it is too loose, the writing will be unclear and the plate will be blurred.

- Speed: If the hot stamping speed is too fast, it will cause the hot stamping to fail or the imprinting will be blurred; if the hot stamping speed is too slow, it will not only affect the quality of the hot stamping but also affect the production efficiency.

In the hot stamping process, the speed, pressure, and temperature are mutually restricted, and the process parameters are always determined in the order of stamping speed, pressure, and temperature. In short, the bronzing process is complicated process technology, and only by grasping the above-mentioned problems in the bronzing process can a satisfactory bronzing effect be obtained.

Wenling Gaobao Industrial Co., Ltd. produces heat transfer foil, heat transfer printing film ,transfer machine, and other products. Welcome to consult!