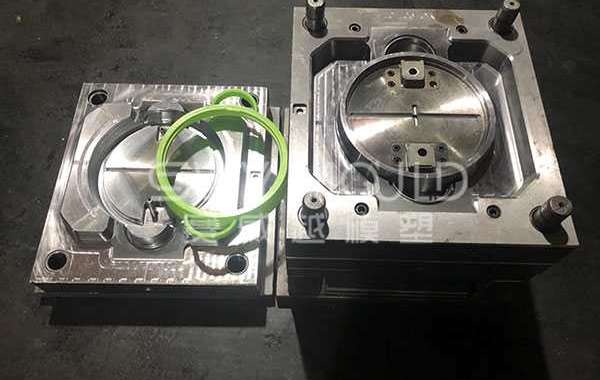

Injection molding can achieve one-time molding of plastic products with complex shapes. It is a high-efficiency and large-scale production method. The pros and cons of injection molds directly affect the quality of injection molding. In the mold industry, if you want to process high-precision, high-quality, and complex-shaped injection molds, you must rely on advanced computer-aided design and manufacturing software to compile reasonable processing procedures. This is to ensure processing quality, improve production efficiency, and reduce Effective way of labor intensity. Four elements of injection molding:

1. Plastic mold 2. Injection molding machine 3. Plastic raw materials 4. Molding conditions

What steps are needed in the process of producing molded plastic products:

First of all, receive the order-product mold design and manufacturing (called: mold opening)-product injection processing-plastic shell surface treatment (oil injection, silkscreen, etc.)-delivery

Types of injection products:

According to user needs, we can tailor the design, develop, produce, and process corresponding injection products, and recommend the best plastic material. Injection molding production involves more than 300 kinds of plastic products in the fields of electronics, instrumentation, IT, daily necessities, etc., and sidewalk color brick plastic mold boxes (more than 100 specifications).

Injection molding is a method of industrial product production modeling

Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding compression method and die-casting method. Injection molding machine (abbreviated as injection machine or injection molding machine) is the main molding equipment that uses plastic molding molds to make various shapes of plastic products from thermoplastics or thermosets. Injection molding is achieved through injection molding machines and molds.

Taizhou Saiweiyue Mould & Plastic Co., Ltd. is an Injection Mould Manufacturers, if you want to know more, please click https://www.swymould.com/