Today's vinyl and polypropylene siding is not the fragile, low-quality cladding on the exterior of your grandmother's house. In fact, according to data from the PVC Vinyl siding Institute 1 (VSI), vinyl siding has been the first choice for single-family houses for more than 20 years. Commercial builders, architects, and renovation contractors have taken note because affordable cladding can also be designated for commercial applications. Standard grade vinyl is mainly used in light commercial and multi-family projects. High-quality and ultra-high-quality polymer panels are used in small and medium-sized commercial projects, such as banks, schools, medical care, and three-story or smaller structures. Owners, architects and contractors saw the value and ability to combine high-end architectural aesthetics and higher weather resistance requirements with strict budgets and shorter construction times.

The latest proprietary technology produced by innovative research and development also means meeting strict local zoning regulations, such as aesthetics, building codes or other regulations, otherwise wood or fiber cement may be the designator’s first choice in new buildings such as multi-family residential developments, offices, etc. And retail buildings, even historic districts and landmark commercial renovation projects. According to the 2018 IBC, vinyl siding should be allowed on the exterior walls of buildings in areas where wind speeds do not exceed 100 mph and the height of the building is less than 40 feet. In Exposure C, when any of these standards are exceeded, IBC requires the submission of tests or calculations demonstrating compliance with IBC Chapter 16. It has been confirmed that high-quality vinyl and polymer siding products meet ASTM wind load standards: ASTM D5206; and approved third-party testing laboratories test to exceed this standard.

The negative stigma of vinyl is disappearing because it is becoming more and more popular in specifying vinyl and the list of properties is very long. It includes lower installation costs, third-party certification, durability and moisture resistance, quick installation, low maintenance, color retention, energy efficiency and sustainability-the green attributes of many products are independently recorded in the Environmental Product Declaration (EPD) And Life Cycle Assessment (LCA).

Rich in aesthetics

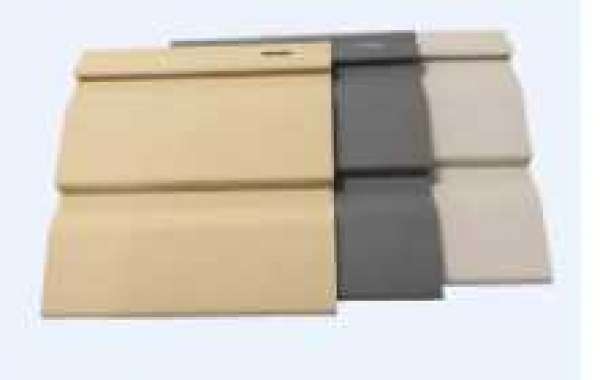

Vinyl siding provides the required architectural versatility and superior durability to realize any design vision, with almost unlimited choices of classic partitions, laps, beading, shaking or shingle profiles, in a variety of styles, fade-resistant colors , Width and texture.

For example, a polymer product line includes eight milkshake and shingle styles, six sizes, and more than 45 colors. Since it was launched nationwide in 1992, it has experienced three generations of innovation. The latest incarnation includes a set of proprietary dyed cedar appearance color mixtures into the product line, which captures the appearance of eastern white cedar and western red cedar at different life stages (from new to weathered). The new patented color technology creates pure color in-mold noise on the entire panel. This is not a coated product, and the owner must worry about flaking or flaking over time. It is easier to install than real wood, but still provides the real look of real cedar shingles. It is so popular that many wood purists-some call them "wood snobs" who were resistant to polymer cladding in the past-have transformed. The panels and individual shingles look so realistic—even when viewed from close range—that many people end up touching and tapping it to prove that it is not wood. Even the wooden shadow lines are more pronounced, the tapered gaps are very close to the panel surface, as they dig deeper.

The color of painted wood and fiber cement requires regular maintenance. High-quality vinyl siding will not chip or peel like paint. It is available in more than 400 VSI-certified colors to provide reliable protection against fading. The high-quality siding manufacturer also provides a lifetime warranty for the product to give you more peace of mind.

Many vinyl and polymer siding products are designed to complement each other, which means less time worrying about what is what. Specifiers can freely mix and match laps and shakes or shingle siding to get a custom look, which can easily create stylish accents to get the amazing factor. In addition, accent colors are often used to make unique architectural features stand out from the main wall colors. Vinyl siding can also be easily coordinated with other materials, such as stone veneers and bricks.

Combine materials to form a bold statement, and add vinyl soffit and vinyl or honeycomb PVC trim to provide a complementary, easy-to-care coordinated style.

In addition, WPC wall cladding is also a very commonly used board in construction.