Gate / Runner Location: This is one of the most important factors to consider during the Filling Stage of the injection process

Coolant Lines: Poor placement or inadequate number of cooling lines result in long cycle times and warpage

Shrink Rate: Shrinkage is generally between 0.4 - 2% and must be taken into account by the mold designer. The exact amount of shrinkage depends on several factors, including material, process conditions, and gate location

Part Tolerances: The tolerances and performance requirements for Mold parts are critical to define prior to launch. It impacts how the tool is built, impacts where to stay “steel safe” with the tool, where to inject the material, and where to eject material. We are seeing more and more parts that are designed using metal tolerances, this drives up costs and extends lead times drastically. An over tolerance part can make or break a tool budget due to the additional steps, stages, or quality checks needed

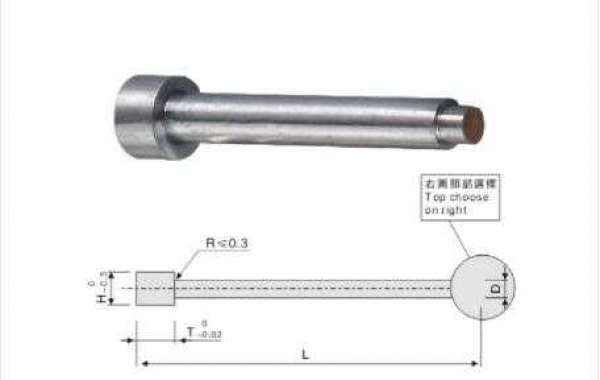

How about buying Guide bush?