Essential to power the modern world

Magnet wire-essential to the world

The wire used for the winding of electrical equipment is called enameled wire (sometimes called motor wire or winding wire). Simply put, copper magnet wire is used to exchange electrical and magnetic energy. The most common enameled wire is the copper insulated wire used in electric motors-one of the greatest inventions ever made, on wheels and light bulbs. Magnet wires can be divided into broad categories, including enameled wires, coated (or service) wires, or a combination of the two.

Magnet wire types can vary, but will include the following characteristics: (a) insulation uniformity, (b) good electrical properties such as dielectric strength and insulation resistance, (c) resistance to mechanical stress, (d) resistance to chemicals , Solvents and encapsulation varnishes, (e) heat resistance and (f) long thermal life. Any enameled wire should exhibit strong characteristics in one or more of these characteristics. Each type has its own advantages and disadvantages. The main idea is that electric current generates a magnetic field. Therefore, when selecting a wire type for any particular application, operating conditions are critical.

The main idea is that electric current generates a magnetic field. You can increase the strength of this magnetic field by increasing the current or making multiple loops.

Magnet wire insulation

Insulation guide

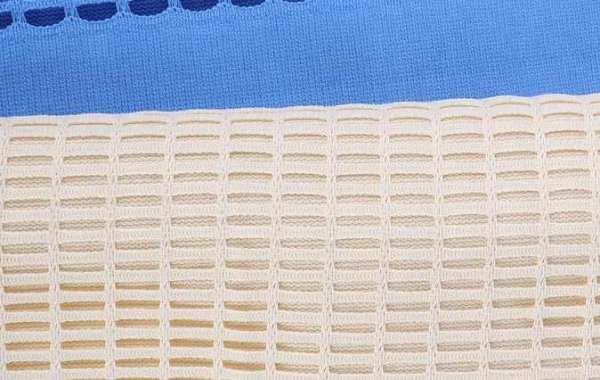

Modern enameled wires usually use one to four build thickness (in the case of the four-layer film type) or polymer film insulation layer, usually with two different compositions to provide a tough, continuous insulation layer. Magnet wire insulation film uses (in the order of increasing temperature range) polyvinyl formal (Formvar), polyurethane, polyamide, polyester, polyester-polyimide, polyamide-polyimide (or amide-acyl Imine) and polyimide. Polyimide insulated enameled wire can operate continuously at temperatures up to 240 °C. The insulation of thicker square or rectangular enameled wires is usually reinforced by wrapping with high-temperature polyimide or glass fiber tape, and the completed winding is usually vacuum impregnated with insulating varnish to improve the insulation strength and the strength of the winding for long-term reliability.

Self-supporting coils are wound with wires coated with at least two layers. The outermost layer is thermoplastic, which bonds the coils together when heated.

Other types of insulating materials, such as varnished glass fiber yarn, aramid paper, kraft paper, mica and polyester film, are also widely used in various applications around the world, such as transformers and reactors. In the audio field, you can find silver wires and various other insulators, such as cotton (sometimes impregnated with some kind of coagulant/thickener, such as beeswax) and polytetrafluoroethylene (Teflon). Older insulating materials include cotton, paper or silk, but these are only suitable for low temperature applications (up to 105°C).

To facilitate manufacturing, some low-temperature enameled wires have an insulating layer that can be removed by welding heat. This means that electrical connections can be made at the ends without first stripping the insulation.

Electric motors are widely used in various products, including fans, household appliances, heavy machinery and automobiles. They come in many shapes and sizes, the smallest for electric watches and the largest for large ships. Some of the benefits of electric motors include low cost, low maintenance requirements, no fossil fuels, and more.

round enameled wire can also be found in transformers, which are essentially devices that transfer electrical energy from one circuit to another through copper coils. Electricity can be transmitted through a magnetic field instead of a metal connection between two circuits. Aluminum wire can be used, but copper enameled wire is preferred because it saves space and can be wound tighter. The impact of transformers has exceeded people's expectations-only a small part of the world's electricity passes through a series of transformers when it reaches consumers.

Conductivity and connection

The debate between copper and aluminum windings in motors is still a hot topic. Today, engineers from all walks of life are questioning whether the quality and performance of aluminum windings can be compared with copper.

What else can the magnet wire do?

Eliminate "mistakes" in military aircraft

Magnet wires can be found in a large number of daily necessities, even on airplanes. Electric model airplanes have been flying since the 1970s, and there was an unconfirmed report as early as 1957. Since then, they have developed into small battery-powered unmanned aerial vehicles or unmanned aerial vehicles, which have been widely used for many purposes in the 21st century.

However, although we may see an electric sports car as fast as Tesla on the earth, the speed in the sky is another matter. Using electricity to actually propel aircraft, especially large and heavy commercial aircraft, is a more complex challenge. In a traditional jet aircraft, the engine sucks in air from the front, the compressor squeezes the air, and fuel is injected and ignited to generate combustion gas and forward thrust. The power supply for electric aircraft is much simpler. The battery powers the electric motor that rotates the propeller. It is more effective, but the thrust involved is much smaller, which is why the choice of ric aircraft is often slow. It may be more environmentally friendly, but for the purpose