After unpacking, you should pay attention to some attentions of heat transfer paper. If it is not used for a long time, it should be placed in the original packaging plastic bag to prevent moisture and damage. Causes color development, etc., affecting use. Before using the product, confirm the position of the printer. When printing in multiple layers, try not to use high-speed printing to ensure the clarity of printed writing. Note that the documents should be stored separately, if they must be stored together, avoid squeezing. It should be protected from light, water, oil, acid and alkali. As long as in the right environment, carbonless printing paper can be stored for at least 15 years. If there is a paper jam during printing, check whether the position of the printing paper is appropriate, whether it is aligned with the tractor, and whether the print head has selected a position suitable for the number of paper layers.

receipt printer or flat push printer, etc. are most suitable for the use of multi-link carbonless printing paper products. These printers are designed so that the printing paper is not bent in the machine, the printing paper is flat, and the printing force is also greater.

sticky sublimation paper does not show color or is not clear (except for the quality of the base paper) how to solve it?

The lack of color may be caused by the reverse loading of the printing paper, just reload the paper.

The cause of unclear color may be insufficient printer pressure or broken needles in the print head. You can increase the printing strength to check whether there are broken needles.

Color development is a chemical process, which is greatly affected by the environmental temperature, especially when the temperature is low in winter, the chemical reaction activity is slow, and you cannot see clear writing immediately after printing. This is a normal phenomenon.

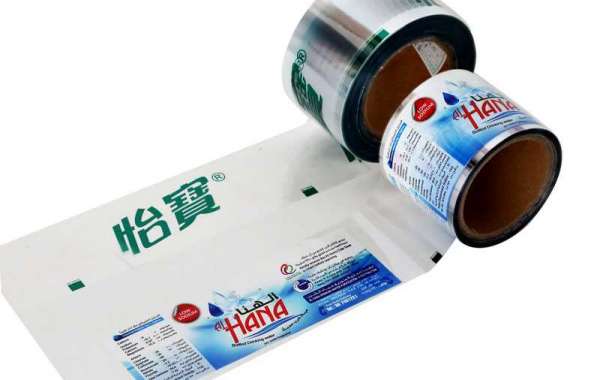

The heat transfer label is also for sale. Contact us if you are interested!