Ensuring the precision and quality of automotive molds is one of the key goals in the design process. Here are some common approaches and considerations:

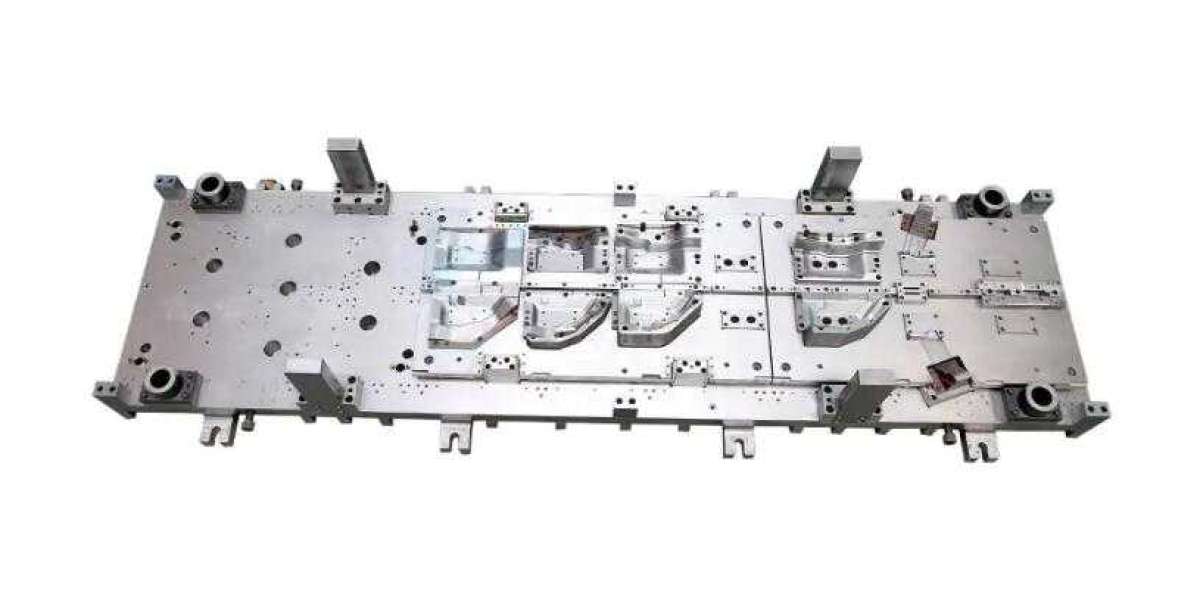

1. Design Accuracy: In the design stage of automotive moulds, precise dimensions and geometries are critical. Use CAD (Computer Aided Design) software to draw and verify the geometric shape of the mold to ensure the accuracy of dimensions and fit relationships.

2. Material selection: Choose high-quality mold materials, such as tool steel, to ensure the strength and wear resistance of the mold. Proper material selection is critical to the life and accuracy of the mold.

3. Precision machining: During the mold manufacturing process, precision machining techniques, such as CNC machine tool machining and electric discharge machining (EDM), are used to ensure the precision and surface quality of mold parts.

4. Cooling system design: In the mold design, reasonably design the cooling system to control the mold temperature and improve production efficiency and product quality. The design of the cooling system should consider factors such as material fluidity, selection of cooling medium, and flow distribution.

5. Precise assembly and debugging: After mold manufacturing is completed, a precise assembly and debugging process is carried out to ensure the correct fit and smooth operation of each mold part. During the debugging process, dimensional inspection and testing can be carried out to ensure that the precision and quality of the mold meet the requirements.

6. Quality control and inspection: Establish a strict quality control process, including inspection of mold parts, dimension measurement and function test, etc. Identify and correct potential problems in a timely manner through the use of inspection tools and equipment.

7. Continuous improvement: During the use of the mold, collect and analyze the user data and feedback of the mold for continuous improvement and optimization. According to the actual production and usage conditions, carry out the maintenance and repair of the mold to maintain the precision and quality of the mold.