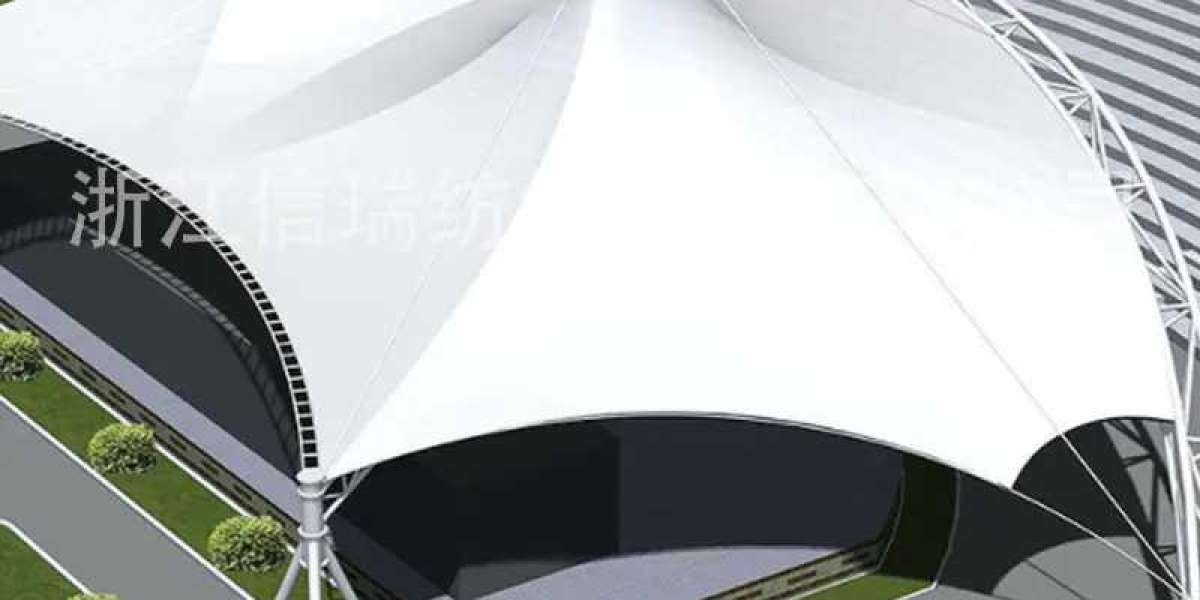

PVC architectural membrane processing is a composite material formed by coating PVC (polyvinyl chloride) resin on polyester fiber base cloth. In order to ensure that the film body has strong aging resistance, weather resistance, mildew resistance, self-cleaning performance and other capabilities, the surface is specially treated.

The surface of the membrane is extremely important. The quality of the surface treatment not only affects the self-cleaning performance of the membrane, but also affects the service life, mildew resistance and UV resistance of the membrane.

At present, there are three common surface treatment methods for membrane materials on the market: acrylic, weldable PVDF and non-weldable PVDF.

Acrylic-treated membrane materials are generally used for tents, truck tarpaulins or advertising fabrics, which have short service life and low tensile strength, and are generally not used in membrane structure buildings.

Weldable PVC membrane, the surface PVDF coating concentration is low, the membrane has almost no self-cleaning, but the price is very cheap.

Non-weldable Pvc membrane material has a high concentration of PVDF coating on the surface, cannot be directly welded, and the processing is complicated, but the surface of the membrane material has obvious self-cleaning properties, but the price is more expensive than the weldable membrane material.

PvC film is widely used because of its relatively low price and performance that meets the design requirements.

Xinrui is a professional Architectural Membrane Manufacturers. For more information, please continue to follow us!