As a Injection mold maker, we know that time is money and one small issue that can be costly in injection molding is bubbling. Bubbles have two primary causes: gas pockets or vacuum voids. Both of these are essentially air-flow related issues.

In order to remedy the situation you need to examine which type of bubble you are dealing with specifically because the quicker you can identify they type of bubble, the faster you can diagnose and repair the issues slowing production.

To be able to differentiate between gas pockets or vacuum voids you can use a simple heat test. By using a hot air gun or small lighter, warm the area of the part that has the bubble until it begins to soften up. If the bubble expands, you've got a gas pocket. If the bubble collapses, it's a vacuum void.

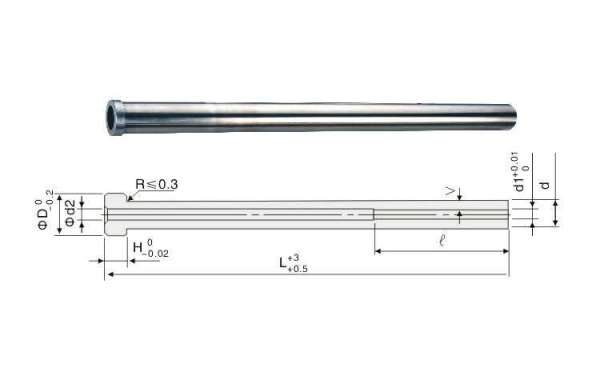

Gas pockets are usually a result of jetting which is a front flow issue. Since this is a venting issue non-vented core pins may be the culprit. These may also lead to excessive decompression which would cause bubbling. Another cause of bubbling may be as simple as moisture. Air flow may become erratic due to moisture in the molding system and this can be a source of trouble.

The issue may be as simple as your material flow. While in process it will be helpful if you check the melt flow pattern by running a few short shots to see if the plastic is jetting around on itself which will cause a pocket to form. Poor melt flow pattern is a major cause of bubbles.

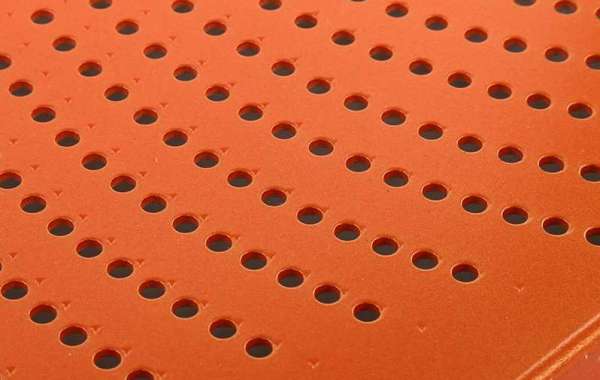

If melt flow is to blame you may need to change the gate location to eliminate air trapping or promote more uniform filling.

While examining the purging of a normal shot, you should also take a look to see if the problem is coming from the barrel or screw. General-purpose screws with dimensions of 18:1 L/D or lower can be the culprits for a bubble or blister. One solution is to raise the backpressure to 1000 to 1500 psi melt pressure. Another solution may be to pull a vacuum on the mold just before injection, so that air is pulled out.

If you've gone over these issues and you are still experiencing trouble, it may be time to disassemble. If you are working with a hot runner air may get sucked between the pates due to a Venturi effect and this air would pocket in the melt and cause bubbling.

This can be checked out by disassembling the machine and placing a bluing agent near the drops. You must be careful to not get any in the flow path. If the bluing agent shows up in your part then you have found the source of your problem.

Since airflow is the major source of the problem, a preventative routine maintenance plan to make sure all heated parts are venting properly will help keep bubbles away. Follow up with periodic machine maintenance and continuous random part inspection and you should keep running smoothly.

If you are interested in Plastic Compression Springs, welcome to your come and purchase!