We can plan suitable solutions according to the customer's factory requirements, capacity planning, automation level and economic cost budget; production equipment and planning for your use. This production line is suitable for crisp biscuits, hard biscuits, fermented biscuits, biscuits, sandwich biscuits, egg biscuits, decoration biscuits.

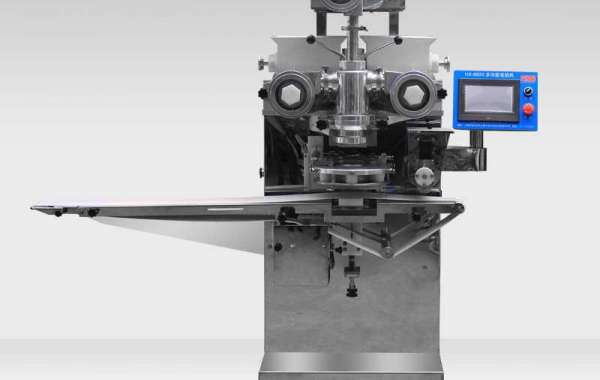

The automatic biscuit production line is the company digested and absorbed Japanese technology, new equipment planning, compact structure, high degree of automation, from feeding to calendering, molding, fertilizer recovery, drying, injection, and cooling. Hanjue Encrusting Machine Manufacturer provides users with thousands of molds and dozens of technical formulas, various high-end biscuits, such as butter biscuits, ultra-thin biscuits, milk biscuits, soda biscuits, animal biscuits, multi-dimensional biscuits, vegetable biscuits, etc. It can be produced by changing the mold and processing formula.

The automatic rolling-cut biscuit production line is made by the company digesting and absorbing Japanese technology. The equipment is novel, compact and highly automated. From feeding to calendering, molding, fertilizer recovery, drying, injection molding, and cooling are all automatically completed. If we use a small biscuit machine to make biscuits at home, we must master the operation process and precautions. How to use Protein Bar Extruder: Put the dough into the cookie maker, after installation, press it on the baking tray, squeeze it hard, then pick it up, shake it twice, and the trick is down.

In addition, you need to pay attention to the following: firstly, you must press the baking tray or other hard objects, otherwise the dough that comes out is silk-packed and cannot be shaped; secondly, pay attention to the dry humidity of the dough. If the dough is relatively dry, Otherwise, it will be too awkward to shake off; also pay attention to the other hand to catch it in time when shaking, or it will fall to the ground and wasted.