Before understanding the principle of electromagnetic induction heating, let me ask myself a question: If there were no induction cookers in the world, what would you do if you had to boil a pot of water?

The most common way is to light the stove and place the pot on the fire.

However, this method is an indirect heating method. The pot is first heated by the heat source, and then the heat is transferred to the food in the pot through the pot. In this series of processes, energy loss will inevitably occur.

So, is there a way to turn the pot itself into a heat source and let the pot boil water directly?

this, we will use induction heating.

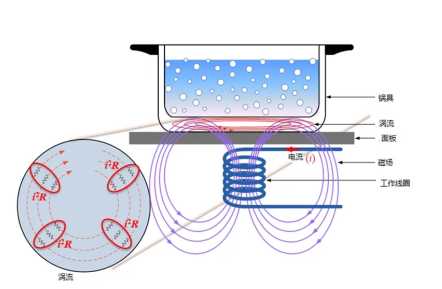

induction heating is shown in Figure 2:

1. The control board generates a high-frequency alternating current through the copper coil through the resonant conversion circuit;

2. An induced magnetic field is generated on the working coil, and the induced magnetic field generates eddy current at the bottom of the metal pot;

3. Eddy currents generate Joule heating through the skin effect of the metal's electrical resistance, and the hysteresis losses associated with the permeability of the material also generate heat.

induction heating speed has the following characteristics:

1. The eddy current at the bottom of the cooking container is proportional to the current flowing through the induction coil, which means that increasing the current of the induction coil will cause the eddy current to increase; the heating time of the cooking container will be faster.

2. A higher frequency will concentrate the eddy current density closer to the surface, which in turn will greatly reduce the cross-sectional area of the active current flow, thereby indirectly increasing the resistance and increasing the heating efficiency, so increasing the operating frequency will also speed up the heating The speed of the container.

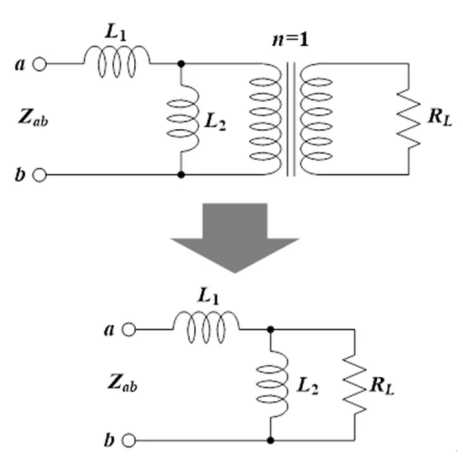

, induction heating requires a resonant controller to generate alternating current on the coil, and in order to achieve a certain power, the current and switching frequency of the resonant controller are required to be relatively high, so the switching device must be selected to be able to conduct large current and fast Switching IGBT.

1. Single-ended resonance is relatively simple to control and has an overall cost advantage;

2. As shown in the following figure, the deficiency of single-ended resonance is that the power range is obviously restricted. Low power (600W) will be hard turned on to generate high current to increase temperature rise, and high power (2.3KW) will be difficult to control the temperature rise of a single tube;

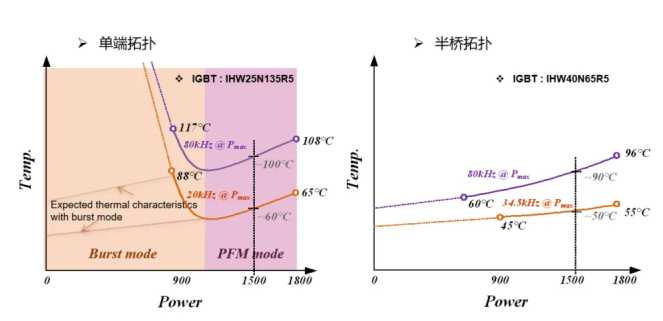

Figure 6. Corresponding relationship between power output and temperature rise of two topologies