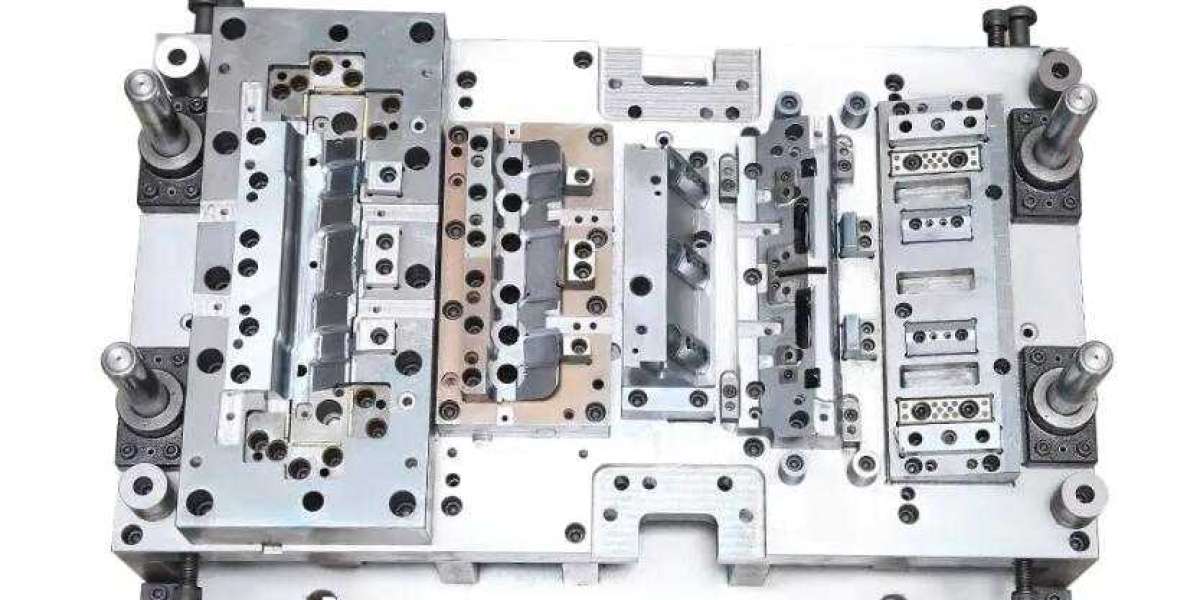

In the world of metal forming and manufacturing, stamping dies play a vital role in producing complex and precise components. Progressive stamping dies have gained significant popularity due to their efficiency and versatility compared to traditional single-stage dies.

(1)Increased Efficiency and Productivity:

One of the key advantages of progressive stamping dies is their ability to perform multiple operations in a single stroke. Unlike traditional single-stage dies, which require multiple setups and manual handling of the part, progressive dies integrate various stations or stages into a single die. This setup eliminates the need for constant material handling and significantly reduces cycle times, resulting in increased productivity and efficiency.

(2)Cost Savings:

The efficiency gained through the use of progressive stamping dies translates into cost savings for manufacturers. By eliminating the need for multiple die setups and reducing labor-intensive operations, companies can produce more components in less time, optimizing their production processes. Moreover, the reduced scrap rates and material waste associated with progressive stamping contribute to additional cost savings.

(3)Consistency and Precision:

Progressive stamping dies ensure high levels of consistency and precision in component production. Each station within the die performs a specific operation with tight tolerances, ensuring uniformity across all parts. The progressive nature of the die enables precise control over critical dimensions, hole placements, and complex features, resulting in parts that meet the required specifications consistently.

(4)Complex Component Manufacturing:

Progressive stamping dies excel in the production of complex components with intricate geometries. By integrating various operations into a single die, manufacturers can achieve complex bending, forming, piercing, and extruding in a seamless process. This capability is particularly advantageous when manufacturing parts with features such as flanges, tabs, threads, or embossing.

(5)Material Versatility:

Progressive stamping dies are compatible with a wide range of materials, including various metals and alloys. Whether it's stainless steel, aluminum, brass, or high-strength steels, progressive stamping dies can handle different materials with ease. This versatility allows manufacturers to adapt to changing material requirements and produce components for diverse applications.

(6)Reduced Lead Time:

The streamlined production process enabled by progressive stamping dies significantly reduces the lead time for component manufacturing. With the elimination of intermediate setups and the integration of multiple operations into a single die, manufacturers can accelerate the production timeline. This reduced lead time enhances their ability to meet tight deadlines and customer demands.

(7)Scalability and Volume Production:

Progressive stamping dies are highly scalable, making them suitable for both low and high-volume production. Once the die design is established, manufacturers can replicate the same setup to produce thousands or even millions of components without compromising quality or consistency. This scalability allows for efficient production planning and responsiveness to market demands.

(8)Enhanced Automation Opportunities:

The progressive nature of these dies lends itself to automation integration. Progressive stamping processes can be easily integrated with robotic systems, feeders, and sensors, further enhancing productivity and reducing manual labor. Automation not only improves production speed but also ensures worker safety by minimizing human involvement in repetitive or hazardous tasks.