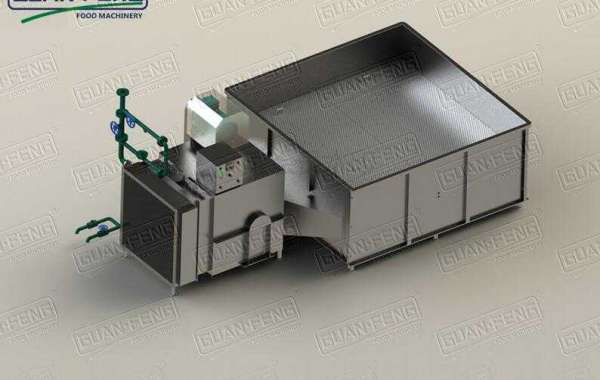

Freeze Dry Machine is a new type of equipment integrating refrigeration system, system, heat conduction oil heating system and dehumidification system. It is suitable for drying high-grade raw materials, Chinese medicinal materials, biology, wild vegetables, dehydrated vegetables, food, fruits, chemicals, pharmaceutical intermediates and other materials.

In the past few years, the freeze-drying industry has made great progress, and the application field of vegetable drying equipment has also continued to expand. Now freeze-drying technology can be used for antibody, protein, tissue and microorganism research, so it has been widely used in the field of biopharmaceuticals.

In the freeze-drying process, what kind of small faults do you usually encounter? Don't worry about these small faults. Guanfeng Machinery lists the common faults and solutions for you. Let's take a look!

One: the temperature in the operating room is too high

The use of freeze dryers also requires the environment. If the indoor temperature is too high, the condenser may not be able to perform its intended function and invalidate the system. Encountered this problem, users can open the back door of the condenser to achieve the effect of ventilation and cooling.

Two: The environmental humidity is too high

If the humidity in the working room of the freeze dryer is too high, it is easy to cause electrical failure or short circuit. If this happens, users need to pay attention to open windows for ventilation.

Three: the power supply voltage is unstable

Generally speaking, the normal working power supply voltage of the freeze dryer is 215-225 volts. If the voltage does not meet the requirements, the machine cannot operate normally. To solve this problem, users need to configure a good quality power supply. If the voltage is unstable, you can use AVR (220V) or add a voltage regulator to the original working power supply.

Four: Excessive dust in freeze dryer or environment

The Vegetable Drying Equipment and the operation room must be kept clean and tidy, and the machine needs to be cleaned regularly, otherwise it will affect the condensation effect of the freeze dryer. Therefore, regularly use a soft brush to remove dust from the compressor, condenser and piping.