In life, common PVC sheets can be made into PVC siding panels and used as interior decoration materials. Usually, the width of PVC board is 1220*2440mm, 1560*3050mm, 2050*3050mm, of which 1220*2440mm is used the most, and the thickness increases from 1mm to 32mm.

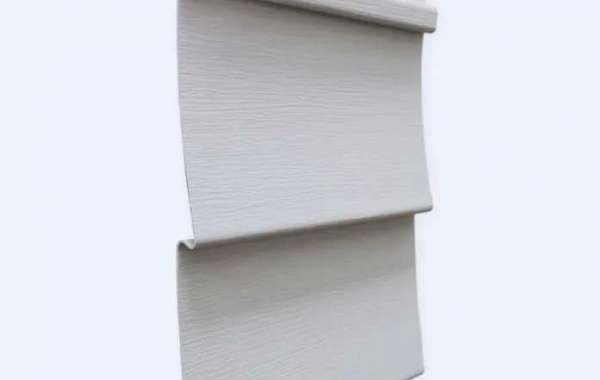

The most commonly used color of PV panels is white, of course, there are also colored panels, but they are rarely used in actual production. If the finished product has to be colored, it can be painted. Under the same thickness, a high-quality PVC sheet has high strength, a hard surface, is not easy to bend, not easy to scratch, not easy to drop ash, and will not turn yellow (white PVC) after long-term use. The poor quality PVC sheet has loose texture, low hardness, uneven surface, and some cut surfaces even have bubble-like lines.

Although the use of PVC sheets is very wide, there are only a few kinds of its processes, and here is a brief introduction.

1. Carving

Engraving is the most common and widely used processing method for PVC sheets. PVC engraving generally uses mechanical engraving, and laser engraving is less used.

Take the production of PVC characters as an example: after engraving the PVC characters, you need to use a blower (or an air compressor) to blow off the fine particles on the surface of the characters, and then polish them.

If you need to paint the engraved PVC products, you need to count the PVC characters and arrange them neatly, and then spray paint to ensure the uniform paint color of the PVC finished products.

PVC word engraving

After finishing the PVC word, it can be put into use. In addition, a layer of two-color board or acrylic can also be laminated on its surface with special acrylic glue to increase its sense of quality. Of course, multiple layers of PVC can also be used to make PVC products with larger thicknesses and more complex processes.

2. Mounting

After the PVC sheet is cut, clean up the impurities on the surface, and then use a laminating machine to mount a layer of the self-adhesive pictures on the surface of the PVC to make a PVC drawing board. The quality of the drawing board is very good. Compared with the KT board, Thicker and more durable.

3. UV

PVC board can be used for UV printing, but when printing, the adhesion of ink to the board needs to be considered. If the adhesion of the ink to the surface of the plate is not strong (scratched off), you can use a special curing agent.

Zhejiang Haichuang Integrated Housing Technology Co., Ltd. is a manufacturer of PVC wall panels and interior PVC wall panels, producing wood bamboo wall panels, PVC Vinyl siding, and other products.