A critical but sometimes overlooked injection plastic mold design consideration concerns the correct mold material selection. Because the choice of mold material will affect the tool life.

The right steel grade and hardness can properly balance wear and toughness so tool components that run together do not wear out prematurely. The hardness of the steel also introduces the brittleness of the steel, and harder steel is not a good choice for tool parts subjected to side loads or impacts, as it will bend and crack. Forming glass-filled materials requires harder steel, which will prematurely wear tooling, including runner systems and gates.

In ensuring an optimized production process, cost reduction and unmatched product quality for injection molds, it is necessary to take into account:

1 Place the waterline to maximize cooling and minimize warping

2 Calculate gate/runner dimensions for proper filling and minimum cycle time

3 Determining the best shutdown method for tool durability over the life of the program

4 Achieving optimum flow, fill pressure, cooling time, and size/tolerance

5 Ensure proper part performance

6 Prevents part defects and cosmetic defects (e.g. flow marks, shrinkage, warpage)

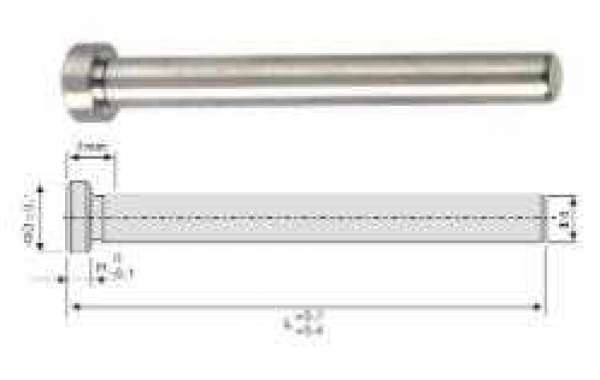

Taizhou Huangyan Jinhong Plastic Mould Parts Co., Ltd. is an injection mold maker from China Ejector sleeve, its own plastic mold factory specializes in the production of plastic compression springs, positioning components, and other products and the company can provide special products.