Automotive Interior parts have excellent weather resistance, ensuring that they will not change color or age and crack after long-term use (including heat-resistant oxygen aging and light aging);

Good chemical resistance to resist the erosion of oil and daily chemicals;

Easy to formability, should have sufficient fluidity for injection-grade materials, ensure the formation of complex parts, and improve production efficiency;

Economical requires materials with high cost performance.

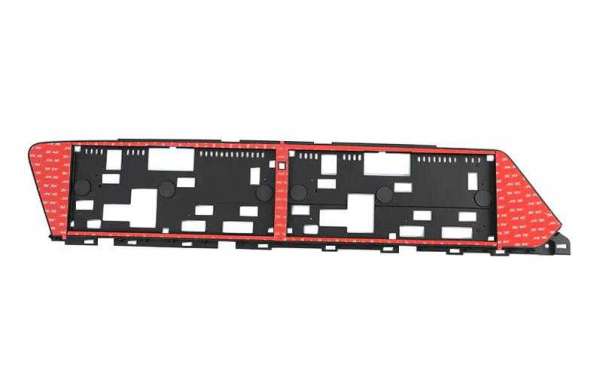

Material requirements for exterior parts

Weather resistance: weather-resistant materials, such as AES, ASA (AAS), PC/PBT (PET), etc., should be used for parts that are not painted or electroplated;

Heat resistance: Due to the low ambient temperature, the standard heat resistance level can meet the requirements;

Low temperature resistance: the material is required to have a certain low temperature resistance to prevent the components from cracking in the low temperature environment in winter;

Chemical resistance: prevent the erosion of oil and acid rain;

Scratch resistance: The material is required to have a certain surface hardness and a low coefficient of friction to prevent scratches.

Material requirements for Plastic parts of car center console

Heat resistance: Due to the long-term sunlight in summer, the temperature inside the vehicle compartment is relatively high, and the interior materials are required to have high heat resistance;

Aging resistance: including thermal oxidative aging and light aging, to prevent aging, discoloration and deterioration of components;

Odor: For the health of drivers and passengers, materials should ensure low volatility and low odor;

Matte: To ensure driving safety, use matte materials or matte textures;

Scratch resistance: The material is required to have a certain surface hardness and a low coefficient of friction to prevent scratching and fluffing.