Power tools have revolutionized various industries, from construction to automotive repair. However, their performance heavily relies on the components that make them efficient and durable. One such crucial component is the rubber seal. Power tool rubber seals play a vital role in ensuring that tools function correctly and have a long service life. In this article, we will explore the types, benefits, and applications of power tool rubber seals, shedding light on why they are indispensable in modern power tools.

What Are Power Tool Rubber Seals?

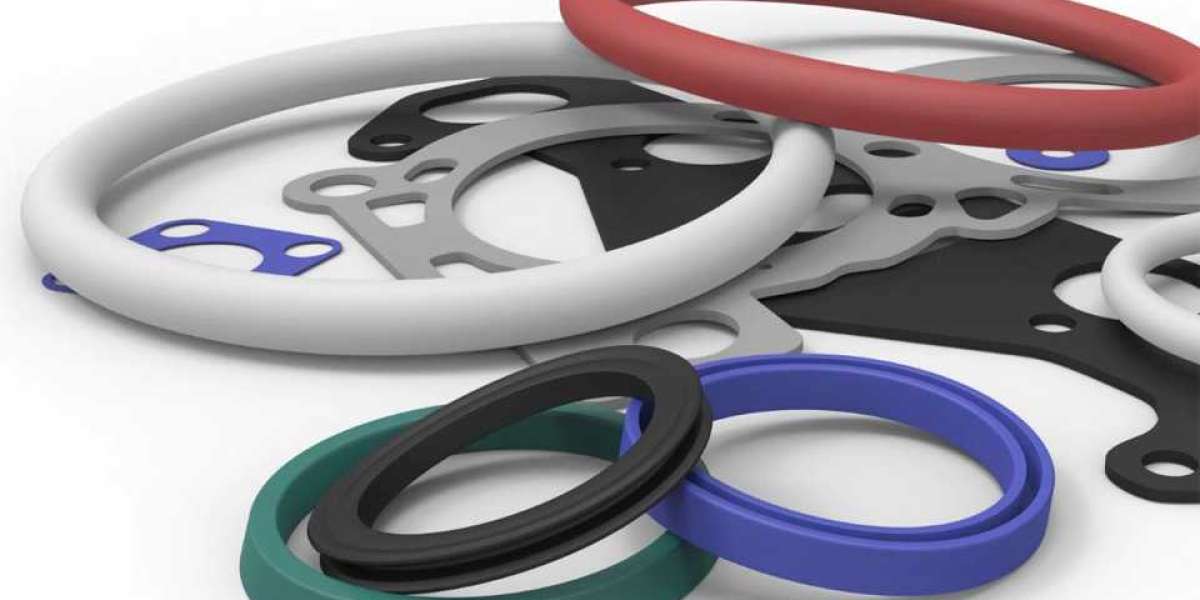

Rubber seals, commonly made from synthetic or natural rubber, are designed to prevent the leakage of fluids and gases while providing protection against dirt and debris. In power tools, these seals help maintain the internal environment of the tool, ensuring optimal performance. They are used in various applications, including electric motors, gearboxes, and hydraulic systems.

Types of Rubber Seals

There are several types of rubber seals used in power tools, each tailored for specific functions:

O-Rings: These circular seals are the most common type found in power tools. They are typically used in static and dynamic applications to prevent fluid leakage. O-rings are known for their simplicity and effectiveness.

Lip Seals: These seals have a flexible lip that contacts the shaft or housing. They are primarily used in rotating applications, providing excellent sealing performance against dirt and moisture. Lip seals are widely used in power tools that have rotating components, such as drills and saws.

Gaskets: Gaskets are flat seals used to create a tight seal between two surfaces. They are often used in power tools where components are bolted together. Gaskets can be made from various materials, including rubber, cork, and paper.

Radial Seals: These seals are designed to fit into a groove on a shaft and provide sealing against radial movement. They are commonly found in gearboxes and other rotating assemblies in power tools.

Face Seals: These seals are used to create a barrier between two surfaces that face each other. They are typically found in high-pressure applications and can withstand harsh conditions.

Benefits of Rubber Seals in Power Tools

Power tool rubber seals offer numerous benefits that enhance the performance and longevity of tools:

Leak Prevention: The primary function of rubber seals is to prevent leaks. This is crucial in power tools that rely on lubricants for smooth operation. A well-sealed tool reduces the risk of lubricant loss, ensuring optimal performance.

Dust and Debris Protection: Rubber seals act as barriers against dirt, dust, and debris, which can cause wear and tear on internal components. By keeping contaminants out, rubber seals extend the life of power tools.

Temperature Resistance: Rubber seals can withstand a wide range of temperatures, making them suitable for various operating conditions. This heat resistance is vital for power tools that generate significant heat during operation.

Vibration Absorption: Power tools often experience vibrations during use, which can lead to component wear. Rubber seals help absorb these vibrations, protecting sensitive components and enhancing tool durability.

Cost-Effectiveness: While the initial cost of rubber seals may seem low, their ability to prevent leaks and extend tool life makes them a cost-effective choice in the long run. Replacing worn seals is much cheaper than repairing or replacing damaged tools.

Customization: Rubber seals can be customized to fit specific dimensions and performance requirements. This flexibility allows manufacturers to design power tools with seals that meet their unique specifications.

Applications of Power Tool Rubber Seals

Power tool rubber seals are used across various applications in different industries:

Construction: In the construction industry, power tools like drills, saws, and nail guns are essential. Rubber seals in these tools help prevent dust and debris from entering sensitive components, ensuring consistent performance even in rugged environments.

Automotive Repair: Power tools such as impact wrenches and pneumatic tools rely on rubber seals to maintain proper lubrication and prevent leaks. These seals ensure that tools perform optimally during repairs and maintenance.

Manufacturing: In manufacturing settings, power tools like grinders and polishers must withstand continuous use. Rubber seals play a critical role in keeping these tools operational by preventing dust buildup and ensuring lubrication.

Aerospace: The aerospace industry demands the highest performance standards. Rubber seals in power tools used for assembly and maintenance must provide reliable sealing to prevent contamination in sensitive applications.

Home Improvement: DIY enthusiasts and homeowners use power tools for various projects. Rubber seals in these tools help ensure that they function correctly and last longer, providing value to users.

Maintenance and Replacement of Rubber Seals

To ensure optimal performance, it is essential to maintain and replace rubber seals regularly. Here are some tips for maintaining rubber seals in power tools:

Regular Inspection: Periodically inspect rubber seals for signs of wear, such as cracks or deformation. Early detection can prevent further damage to the tool.

Cleaning: Keep the seals clean from dust and debris. Regular cleaning helps prevent buildup that can compromise the seal’s effectiveness.

Lubrication: Some rubber seals benefit from lubrication to maintain flexibility and prevent hardening. Use manufacturer-recommended lubricants for optimal results.

Replacement: When a seal shows significant wear or damage, replace it promptly. Operating power tools with worn seals can lead to leaks and decreased performance.

Choosing the Right Rubber Seal

Selecting the appropriate rubber seal for a power tool involves considering several factors:

Material: Different rubber materials offer varying levels of resistance to heat, chemicals, and wear. Choose a material that meets the specific demands of the application.

Size: Ensure that the seal fits the dimensions of the tool. An improperly sized seal can lead to leaks and reduced performance.

Application Type: Consider whether the seal will be used in a static or dynamic application. For rotating parts, lip seals or radial seals are often more suitable.

Environmental Conditions: Assess the conditions in which the power tool will be used. Factors such as temperature, humidity, and exposure to chemicals can influence the choice of seal material.

Power tool rubber seals are essential components that contribute significantly to the performance and longevity of tools. Understanding the different types of rubber seals, their benefits, and applications is crucial for anyone involved in using or maintaining power tools. By choosing the right seal and ensuring regular maintenance, users can enhance the reliability and effectiveness of their power tools, ultimately leading to improved productivity and cost savings.

Whether you’re a professional tradesperson or a DIY enthusiast, recognizing the importance of rubber seals in power tools will help you make informed decisions and ensure that your tools operate at their best for years to come.