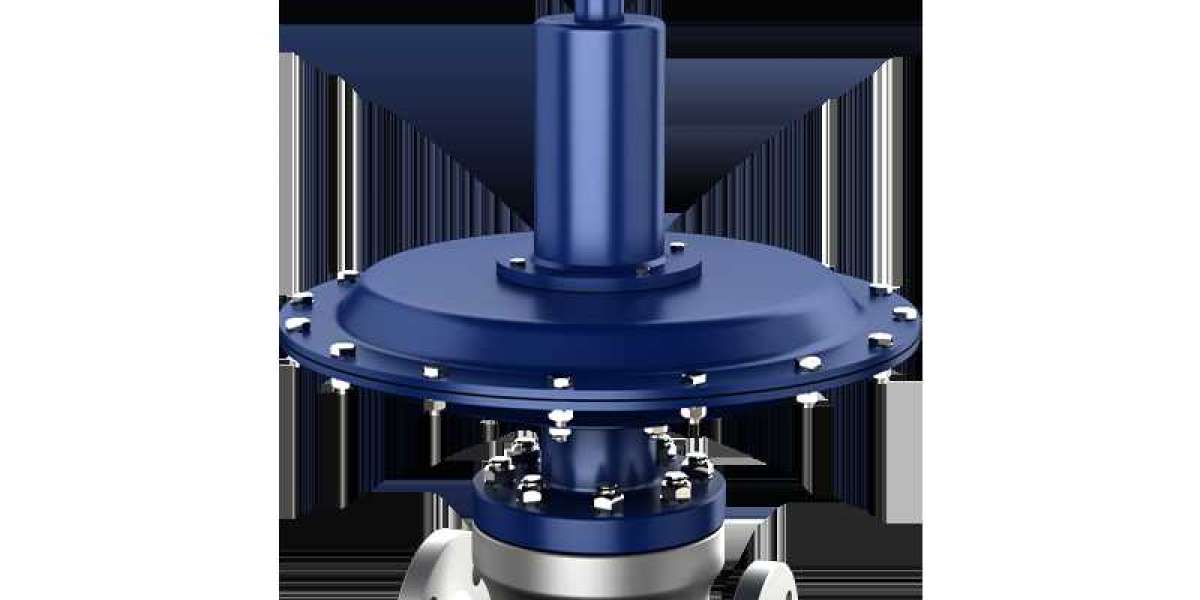

Rotatable diverter reversing valves (WZKs) widely used for distributing and collecting powders as well as granular materials throughout pneumatic conveying ranges, while gravity applications utilize it to transfer material between sources in addition to locations, Custom Nitrogen Sealing Valve China such while blenders, bins or even silos. Their unique asymmetric style and design provides high put on resistance making the WZK a superb choice when management potentially abrasive products like grains.

Coperion's WZK Diverter Valve is a original worldwide state of the art diverter valve as well as widely utilized all around food applications throughout the world. Diverter valves play an essential role in taking care of material flow not having interrupting conveyor techniques - thereby acting as one of several primary preventive mechanisms against contamination during move processes.

Due towards the WZK's dual-inlet feature, its cylinder starts rising smoothly as well as rapidly without lunging as well as bouncing; at relaxation in Figure 8-60, air pressure about its cap end is more or less balanced by upward force at rest; reaching full elevation within seconds once any shift occurs.

When the directional control device shifts to retract, the cylinder lowers as rapidly and well. Utilizing a twin inlet pressure routine, one cap conclude port has EIGHTY psi while solely 15 psi is out there on rod end port per inlet pressure enterprise - creating an enormous differential between air conditioning pressure on cap end port in addition to load. At center position of directional control device centering up force is about 720 pounds via air pressure although load is around 800lbs; providing a huge differential between up and down forces and preventing lunging precisely as it retracts.

Diverter valves feature a modern, patent-protected structure. Their rotatable diversion member might be rotated from it's initial position into any of some subsequent positions regarding easy use. Within the first position, the 2nd opening (72) is closed insurance policy coverage third one (74) will be open; in your second position, however, its opposite occurs: within this instance the subsequent opening (72) goes into business while its counterpart closes; while finally around its final state through which its opposite occurs when both opportunities (72) open simultaneously and close simultaneously : before being joined up with together again when shown above inside Figure 4A as well as C respectively. By making two diverting information inversely oriented, this contains much larger capacity inside a much smaller footprint compared to conventional diverter valves. In addition, this solution provides safe and effective control of detrimental, toxic or corrosive resources in pneumatic with systems. Gravity transfer applications provide a safe, cost-effective and efficient solution for any delivery of powders and also granular materials inside gravity transfer programs. Furthermore, this device connotes an economical different than more complex devices like rotary actuators. Moreover, it has a small footprint and isn't going to require pneumatic push or complex piping to operate effectively. Furthermore, you can clean while getting highly reliable in addition to durable enough pertaining to field service assist. Plus, different patterns, sizes and specifications exist so that you can meet any application's exclusive requirements.